13

Henrad CC FF

- Installation

8

UNPACKING

9

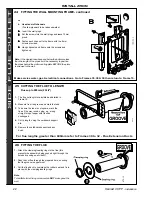

PACKAGING AND FRONT PANEL REMOVAL

Pack B1 Contents

!

Terminal grille assembly

!

No.8 x 8mm self tapping screw - 3 off

!

No.10 x 2" slotted Rd. Hd. screw - 4 off

!

Flue support cutting aid - 1 off

!

Wall plugs - 4 off

!

Terminal wall plate - 1 off

1. Remove the lid.

2. The top tray contains:

!

Flue turret

!"

Mounting frame

!"

Hardware pack

!"

Stand-off channels

!"

Wall mounting template

!"

Installation instructions

These contents can be removed, leaving the boiler in its protective package.

INSTALLATION

INST

ALLA

TION

Optional extras, if ordered, are available in separate boxes.

!

45

0

Elbow Kit

!

Roof Flue Kit

!

Timer Kit

!

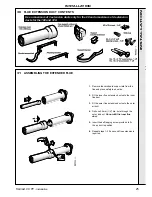

Extension Duct Kit

!

90

0

Elbow Kit

The boiler is supplied fully assembled in one pack, together

with a standard flue assembly for lengths up to 600mm, rear

or side flue outlet, in Pack B1.

Unpack and check the contents.

Boiler Pack Contents

!

The boiler.

!

These Installation & Servicing Instructions.

!

The User's Instructions.

!

Wall mounting template.

!

Wall mounting frame.

!

1 pair stand-off channels (optional use).

!

Flue turret.

!

Clamping and sealing ring.

!

Mains connector assy.

!

Hardware Pack.

!

Coupling Hardware Pack.

Hardware Pack

!

M6 x 16 Pp. Hd. screw - 4 off.

!

1/2" x 15mm copper connector - 1 off.

!

No.14 x 2" slotted Rd. Hd. screw - 6 off.

!

Wall plug (brown) - 6 off.

!

1/2" Nut - 2 off.

!

M28 Nut - 2 off.

!

22mm pipe connector - 2 off.

!

15mm pipe connector - 2 off.

!

22mm x 15mm reducing coupling - 1 off.

!

Pressure relief valve drain pipe - 1 off.

!

Pressure relief valve nut - 1off.

!

Gas pipe assy. - 1 off.

!

22mm olive - 2 off.

!

15mm olive - 3 off.

!

26mm Sealing washer - 3 off.

!

12mm Sealing washer - 3 off.

Coupling Hardware Pack.

!

28 x 22 mm straight coupling

.

Filter Hardware Pack.

!

DHW inlet filter (standard on 80 only)

Summary of Contents for CC 100 FF

Page 1: ......