47

Henrad CC FF

- Installation

76 PRESSURE RELIEF VALVE (Safety Valve) REPLACEMENT

77

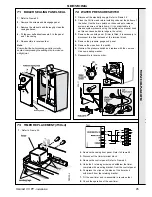

CH EXPANSION VESSEL REPLACEMENT

SERVICING

SER

VICING

1. Isolate the electrical supply. Refer to Frame 54.

2. Remove pump. Refer to Frame 69.

3. Disconnect the mains electrical connection from the

bottom panel. Disengage the 2 halves of the connector.

4. Remove the boiler bottom panel.

5. Close the cocks on the CH flow and return pipework

below the boiler. Drain down. Refer to Frame 68.

6. Disconnect the discharge pipe to the pressure relief valve.

7. Undo the connection securing the valve to the boiler.

8. Replace with a new valve and restore the pipework, in

reverse order, using new sealing washer.

9. Open cocks, fit filling loop, fill, vent and pressurise to 1 bar

(or as required).

10. Restore the electrical supply and set the heating controls,

to test-fire the boiler.

11. Vent air and top up the pressure again, as required.

12. Remove the filling loop.

If the CH expansion vessel is faulty, there are 3 options:

A. If it has a punctured diaphragm, but is

otherwise leak free, then

it can be left in place and a new vessel added to the system,

external to the boiler, provided it is of adequate capacity and

pre-charge pressure.

B. If there is at least 600mm clearance above the boiler, the

expansion vessel can be changed without removing the boiler

(RH exit flues will have to be disturbed). Access to the water

connection of the expansion vessel is

either by removal of the

right hand side boiler panel (if there is 200mm RHS clearance)

or by removal of the fan and gas valve.

C. If there is insufficient headroom, the boiler will need to be

removed. In this case, access to the water connection of the

expansion vessel will be possible by removing the RH boiler

side panel.

For option B, proceed as follows:

B1. Isolate the electric, gas, and

water services.

Summary of Contents for CC 100 FF

Page 1: ......