44

Henrad CC FF

- Installation

SERVICING

SER

VICING

70 HEAT EXCHANGER REPLACEMENT - continued

21. Remove the 2 nuts securing the left support bracket to the

chamber side and remove the left support bracket.

22. Supporting the weight of the heat exchanger, slacken the

screw on the right support bracket and allow the bracket to

its lowest position.

23. Lift out the heat exchanger.

24. Re-assemble in reverse order, using new gaskets as

appropriate.

25. Before refitting the fan, ensure the wires have been

reconnected to the:

- CH thermistor (

violet pair)

- HW thermistor (

grey)

- Flame detection electrode (

yellow)

26. When re-assembly is complete, fit the filling loop, close all

drain points, open all isolating valves and ensure that the

boiler is filled, vented of air and pressurised before

attempting to fire it.

27. After a satisfactory test firing, remove the filling loop (this is

a requirement of the water bylaws).

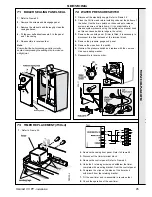

4. Remove the bottom panel.

5. Attach drain pipes to the 2 boiler drain points. Open the CH

drain by turning the grey knobs and the HW drain by

slackening the drain point. Note the marking on the bottom

of the valves. Refer to Frame 68.

6. While the boiler is draining, release the turret clamp on top

of the boiler, together with the screw securing the turret to

the flue pipe. Remove the turret.

7. Remove the fan, venturi and sensing pipe. Refer to

Frame 49.

8. Unscrew and remove the HW expansion vessel.

9. Undo the 2 extended nuts securing the gas injection pipe

and remove.

10. Disconnect the spark electrode leads and the flame sensing

electrode lead at the burner base. Refer to Frame 58.

11. Remove the 3 screws securing the burner assembly and

withdraw the assembly downward, taking care not to

damage the electrodes. Refer to Frame 60.

12. Unplug the electrical leads from both CH and HW

temperature sensors and HW overheat thermostat.

13. Unscrew the nut securing the bottom of the HW inlet pipe

together with the hexagon socket screw retaining the upper

end. Rotate the pipe to clear the bulkhead connector and

then pull down to remove.

14. Unscrew the nut on the CH flow and return pipes to the

heat exchanger.

15. Unscrew the nut securing the bottom of the HW outlet pipe

together with the hexagon socket screw retaining the upper

end.

16. Unscrew the locknut on the bulkhead fitting for the HW

outlet pipe.

17. Unscrew the compression nut securing the HW outlet pipe

to the pre-piping frame.

18. Pull down the HW outlet pipe to remove.

19. Unscrew and remove the automatic air vent from the top of

the heat exchanger.

20. Remove the 2 screws securing the heat exchanger to the

support brackets, together with the top clamping screw.

Summary of Contents for CC 100 FF

Page 1: ......