27

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

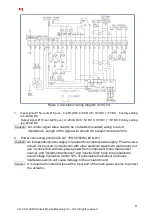

2.5 Connections

2.5.1 Suction/discharge/economizer flange size

Figure 2.2 Flange size

Position

Size

A

B

D

E

F

G

Piping

thick

(JIS)

(GB)

(GB)

RT-120~140

RT-111

Suction

8"

218

221.5

305

350

30

12

25

11

Discharge

6"

167

170.5

260

305

28

12

25

10.5

Mid.-press.

(Eco.)

2 1/2"

77.5

77.5

140

175

20

8

19

7

RT-160~280

RT-161, RT-221

Suction

12"

320

327.5

430

480

36

16

27

14

Discharge

8"

218

221.5

305

350

30

12

25

11

Mid.-press.

(Eco.)

4"

116

116

185

225

24

8

23

8.5

Remarks

※

Material-standard JIS 20 kg/cm

2

g steel unit: mm

※

thickness must be equal to the standard or larger

Table 2.5 Flange dimensions

Note

:

1. Please weld steel pipes onto flanges by butt-welding and make sure debris has

been cleaned, otherwise the compressor might be damaged badly during running.

Flow velocity in the discharge side of the compressor could be as high as

15~20m/sec. High-speed discharge gas will make noise in discharge connection.

In order to decrease the noise level, it’s recommended to round sharp edges of

joints of piping.