Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

3.1.1 Control of inlet

Angles of inlet guide vanes

lever arm. Automatic adjustment of

load with vanes widely opened

The percentage of Actuator

linearly proportional. But the angle change of the inlet guide vane does not show a

relationship with the capacity change, so the percentage of

equivalent to the percentage of frozen capacity load

1. When IGV1 is fully close, a small opening is formed in the central portion to maintain

the basic flow of refrigerant to the compressor. The refrigerant flow is at minimum

when the inlet flow guide vane is completely closed. The freezing capacity at this point

is also at the minimum, but often in the surge zone which cannot be used. Normal

operation IGV1

≧

10% uses (T series IGV1

Note 2: The lower pressure ratio stands for

Therefore, it is NOT applied to all operation conditions that

Actuator could be set less than1

for details of opening of guide vanes

3. When the inlet guide vane of the compressor inlet is

continue to output torque while the

point as the transmission mechanism (guide vain mechanism)

Actuator motor is locked rotor leading to the temperature protection jump

phenomenon), and long-term operation will cause adverse effects on the

order to solve this problem, the

0% to 100% (input signal is 4mA ~ 20mA)

after the unit is switched on with self

turning off the unit to avoid operation

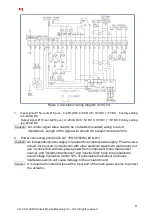

Figure

Min. mass flow

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

nlet guide vanes

nlet guide vanes are automatically controlled through a vane

utomatic adjustment of angles of guide vanes is made with loading,

ed to minimum load with guide vanes completely closed.

Actuator opening and the controlling current (pressure) signal are

linearly proportional. But the angle change of the inlet guide vane does not show a

relationship with the capacity change, so the percentage of Actuato

the percentage of frozen capacity load.

, a small opening is formed in the central portion to maintain

the basic flow of refrigerant to the compressor. The refrigerant flow is at minimum

nlet flow guide vane is completely closed. The freezing capacity at this point

is also at the minimum, but often in the surge zone which cannot be used. Normal

10% uses (T series IGV1

≧

5%).

The lower pressure ratio stands for the lower minimum unloading capacity.

Therefore, it is NOT applied to all operation conditions that opening of the vane

set less than10

%

. Please refer to HANBELL selection software

opening of guide vanes in percentage before operation.

When the inlet guide vane of the compressor inlet is fully close, the

continue to output torque while the Actuator micro switch has not yet functioned

point as the transmission mechanism (guide vain mechanism) has been

motor is locked rotor leading to the temperature protection jump

term operation will cause adverse effects on the

order to solve this problem, the Actuator is set from the factory to operate range from

0% to 100% (input signal is 4mA ~ 20mA). Please set to 5% ~ 100% (4.8mA ~ 20mA)

after the unit is switched on with self-test. Please set to 5 % (4.8mA) when starting and

turning off the unit to avoid operations below 5%.

Figure3.3CloseInlet guide vanes completely

35

automatically controlled through a vane actuator with a

with loading, from full

completely closed.

opening and the controlling current (pressure) signal are

linearly proportional. But the angle change of the inlet guide vane does not show a

Actuator opening is not

, a small opening is formed in the central portion to maintain

the basic flow of refrigerant to the compressor. The refrigerant flow is at minimum

nlet flow guide vane is completely closed. The freezing capacity at this point

is also at the minimum, but often in the surge zone which cannot be used. Normal

the lower minimum unloading capacity.

opening of the vane

HANBELL selection software

re operation.

, the Actuator motor will

o switch has not yet functioned. At this

has been fully close, the

motor is locked rotor leading to the temperature protection jump-off (overload

term operation will cause adverse effects on the Actuator. In

is set from the factory to operate range from

5% ~ 100% (4.8mA ~ 20mA)

test. Please set to 5 % (4.8mA) when starting and