50

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

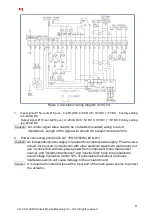

VSD capacity modulation strategy & variable frequency surge formulae

VSD capacity control takes variable speed as priority and IGV as auxiliary for modulation to reach

the optimum efficiency. Thus, VSD compressor surge formulae mainly control the compressor

frequency. The expressions are as follows:

:

Z=a+bx+cy+dx

2

+ey

2

+fxy+gx

3

+hy

3

+ixy

2

+jx

2

y

where a

、

b

、

c

、

d

、

e are constants (refer to Table 3.7

VSD compressor

surge formula);

x=IGV(%) opening (10~100);

y=pressure ratio, Pr;

Z (minimum allowable operating frequency) = Frequency (Hz)

※

Insert the value of y (pressure ratio) and x (IGV opening) at the operating point into the formula

to obtain the minimum allowable operating frequency. The recommended compressor operating

frequency is Z+1 to 1.5Hz in order to reach the maximum efficiency. Reasons for setting value

range of +1 ~ 1.5Hz is:

a. To avoid forced increase in frequency at small IGV openings when IGV opening value is

inserted into the formula (could cause fluctuation of chilled water temperature).

b. To avoid surge formula deviation or inaccurate measuring sensor;

c. This formula does not have safety margin.

Model

Z= a+bx+cy+dx

2

+ey

2

+fxy+gx

3

+hy

3

+ixy

2

+jx

2

y

x=IGV opening(10~100%),y=pressure ratio Pr,Z=Frequency (Hz)

RT-120E

a

b

c

d

e

-3.01 -5.25339E-02 7.01 1.28399E-03 -2.01

f

g

h

i

j

-2.20465E-02 -8.07113E-06 2.00 -1.42502E-03 1.35207E-04

RT-130E

RT-140E

a

b

c

d

e

-2.01 1.11192E-01 4.01 -7.54248E-04 -1.01

f

g

h

i

j

-5.47750E-02 -6.23802E-06 1.00 -1.95358E-02 9.99493E-04

RT-160E~

RT-280E

a

b

c

d

e

-3.01 -1.40837E-02 6.01 2.73888E-04 -2.01

f

g

h

i

j

-3.93628E-02 -9.02008E-07 2.00 3.62232E-03 1.55530E-04

Table 3.7 VSD compressor (50Hz) surge formula (without safety margin)

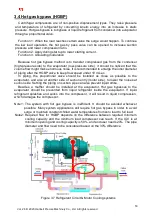

1. Start-up frequency: As high and medium pressure has not been established before start-up, it

is impossible to calculate the required minimum rotational speed based on the pressure ratio

when the compressor starts, therefore it is necessary to estimate the condensing temperature

by using cooling water inlet temperature plus a temperature difference (7~8K) to obtain the

expected condensing pressure. Then, using chilled water outlet temperature minus a

temperature difference (1~2K) as the expected evaporation temperature to obtain the

evaporation pressure. Finally, insert the pressure ratio based the estimated pressures and

IGV=10% into the formula to calculate the minimum operable fr1Hz; otherwise

start-up with the highest operating frequency.