32

Save Project –

click here to save the data already

recorded.

Note

- Plane6 has an auto-saving feature. See page

19

Restoring File Backup

to see how to recover data

from backups.

Clear All

– this clears all the data from all the

line segments recorded for the plate.

Clear Line XX

– this clears all the data from the

line segment currently selected.

Previous Point

– this moves the target icon

(cursor) the previously recorded point to re-

record it.

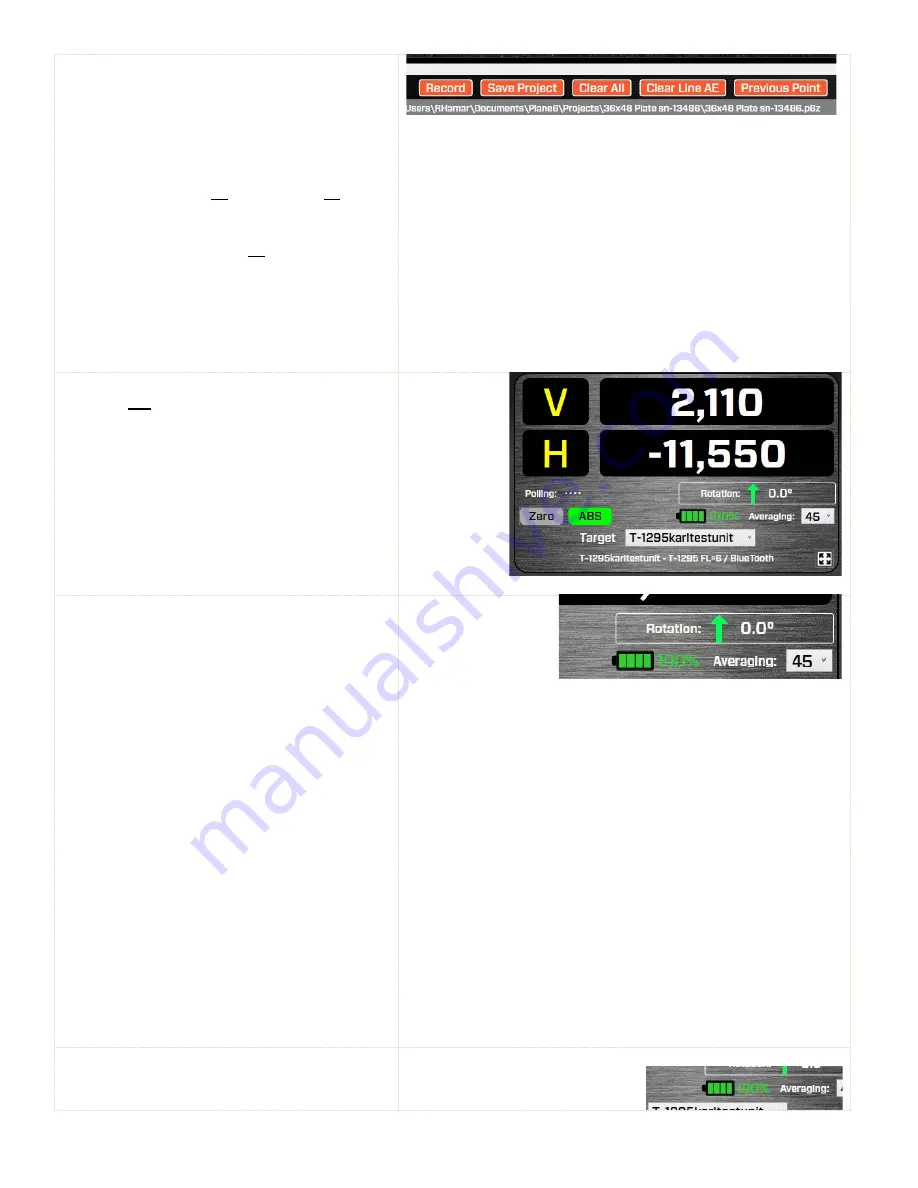

Zero

– Click here to zero the display. This is

generally

not

needed to record the data but may

be useful when sampling small areas of the plate.

ABS

– Click here to return the data display to the

absolute (raw) value display from the target.

This is a measure of how far from the PSD

sensor’s center the laser beam is located.

Normally ABS Mode is used for recording data.

Averaging

– enter values from 1 to 500 and this

will change the number of samples Plane6 uses

to average for each of the values shown in the

data displays.

This also changes the amount of sampling the

software takes when recording a data point. So a

value of 45 means that Plane6 will record 45

target values, average them and record the

averaged value as the data value for that point.

Note:

The higher the averaging value, the more noise

fluctuations will be dampened out, but also the slower

the response time for movements in the laser position.

The data updates at ~13 readings per second, so with

an averaging value of 26, the data takes about 2

seconds to update after the laser beam position has

started moving.

The recommended starting value for most small-to-

medium plates in good environmental conditions is 45

(~4 seconds per point) for A & B grades. If doing AA

grade, then up the sampling to 90 (8 seconds per

point).

Target Battery Icon –

displays the estimated

remaining battery life of the target. It updates

continuously.

Summary of Contents for L-703SP

Page 1: ......

Page 54: ...50 An example on how to do the Math to get the exact flatness values...

Page 55: ...51 Plane6 Sample Report...