6

2

13

1

21

3

5

8

7

Operating

43

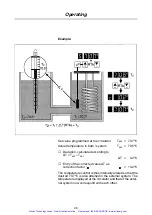

20. Operating

20.1 Switching on

1

Set the excess temperature protection clearly above

the desired operating temperature using the dial 13.

2

Switch the circulator on at the mains switch 1.

This causes:

⇒

The version number of the operating software is briefly

shown at display 6: e.g. “n 1.5”

⇒

Display 6 flashes over all segments

3

Press the Reset key 2 (= start).

⇒

Display 6 shows the actual temperature at the control

sensor (resolution 0.1

°

C).

⇒

Pump motor starts up – the heat transfer liquid starts

to circulate.

The cooling unit is switched on via its own mains switch 21.

Only activate cooling device if cooling is actually required.

The compressor starts with a slight jerk.

20.2 Starting up again after a power failure

The temperature control module switches itself off in case of

a power failure. Display 6 flashes over all segments .

Switching on again is only possible after the reset key 2 has

been pressed. This is due to safety reasons.

The unit reacts in the same way if is switched on via a mains

switch in the laboratory.

You can choose if you want to retain these standard default

settings. The units can be switched to automatic resetting in

both cases mentioned above. This is activated via a sepa-

rate menu option which can be accessed by pressing the

“menu”-key 3 whilst simultaneously switching on the unit.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com