G0620 Main Control Panel

-7-

Blade Tilt

Adjustments

The blade tilt can be adjusted manually or auto-

matically with numerical input. The adjustment

can be cancelled at any time by pressing the Stop

key.

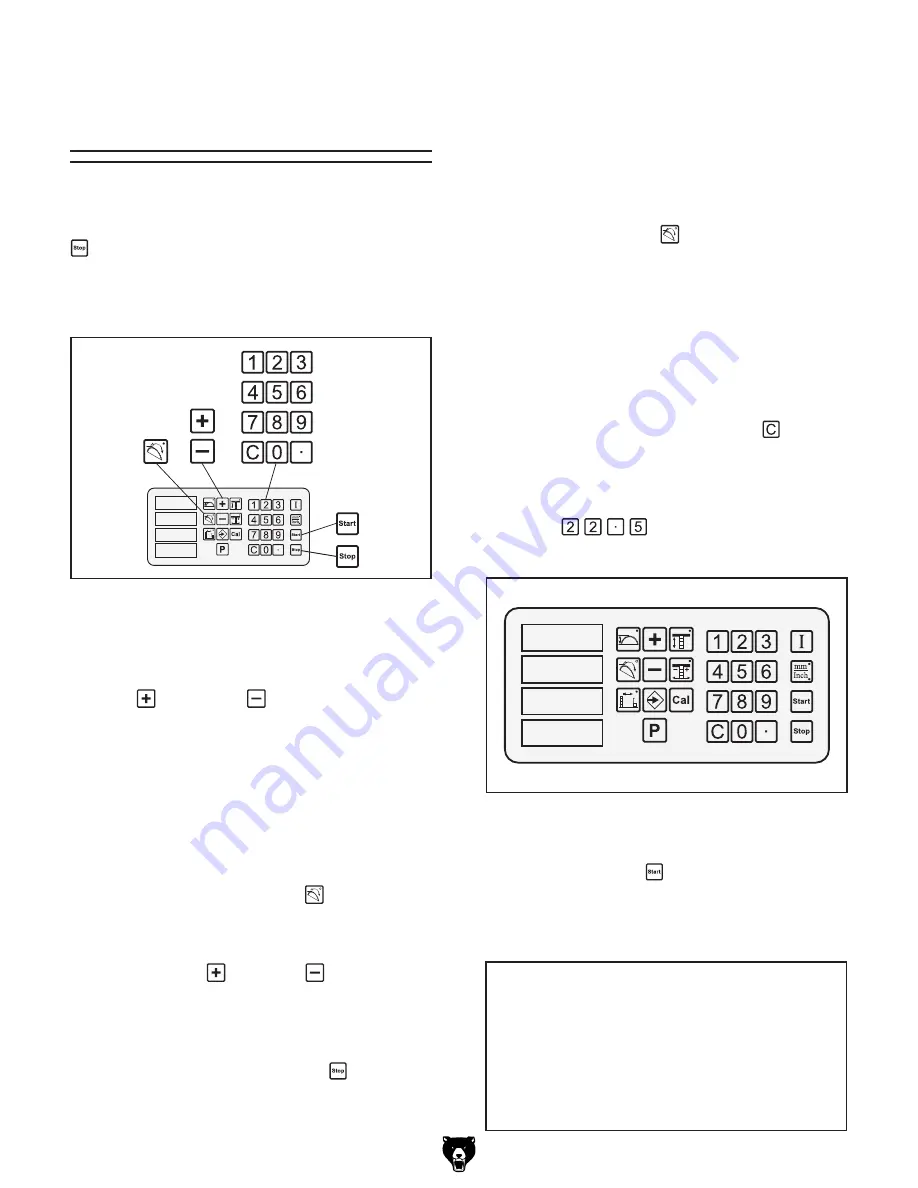

Figure 8

shows the keys used during the blade tilt

adjustment procedures in this section.

Numerically Adjusting Blade Tilt

You can enter a desired angle with the number

keys and the blade will automatically adjust to that

angle.

To adjust the blade tilt automatically with

numerical input:

1.

Press the blade tilt key.

The indicator light on the key shines to tell

you that the control panel is ready to accept

your input.

2.

Enter the desired blade tilt with the number

keys. As you press the keys, the display will

flash the numbers you have entered. If you

press a wrong number or make a mistake

with your input, press the clear

key and

start over.

Example:

If you want the blade tilt to be

22.5", then you would press the following

keys:

, and the display would look

similar to

Figure 9

.

����

����

�

����

Figure 9.

Example of 22.5° entered into blade tilt

display.

3.

Press the Start

key. The control panel

accepts your input, moves the blade to your

desired tilt, and the indicator light on the

blade tilt key stops shining.

Manually Adjusting Blade Tilt

The blade tilt can be manually adjusted using

the plus

and minus

keys. In some cases,

manual adjustments can save time by eliminating

measurements. For example, if you want to adjust

the blade tilt to match an existing mitered cut, you

can place the workpiece next to the blade and

use the manual controls to adjust the blade tilt as

desired.

To adjust the blade tilt manually:

1.

Press the blade tilt control

key. The indi-

cator light on the key shines to show that the

control panel is ready to accept input.

2.

Use the plus

or minus

key to manu-

ally position the blade tilt. (Bump the keys for

small adjustments and hold the keys down for

large adjustments.)

3.

When finished, press the Stop key, so the

indicator light stops shining.

�

�

�

����

Figure 8

. Keys used in blade tilt adjustment

procedures.

NOTICE

Changes to the blade tilt affect blade height.

After performing Step 3, the blade height

will be different than shown in Figure 9. To

save time of having to re-enter the blade

height, enter the blade tilt before entering

blade height.