G0620 Main Control Panel

-19-

Using Offsets

The crosscut fence includes three origin blocks

located inside the channel where the stop blocks

slide in the fence.

The origin block closest to the blade is the "Home"

origin block for the digital stop, which is always

used in conjunction with the other two origin

blocks when the second stop block is used. Using

the second stop block with the origin blocks is the

only way to get a digital reading with the second

stop, and hence, when using the fence extension

(

Figure 36

).

���

������� �������

�

�����

���

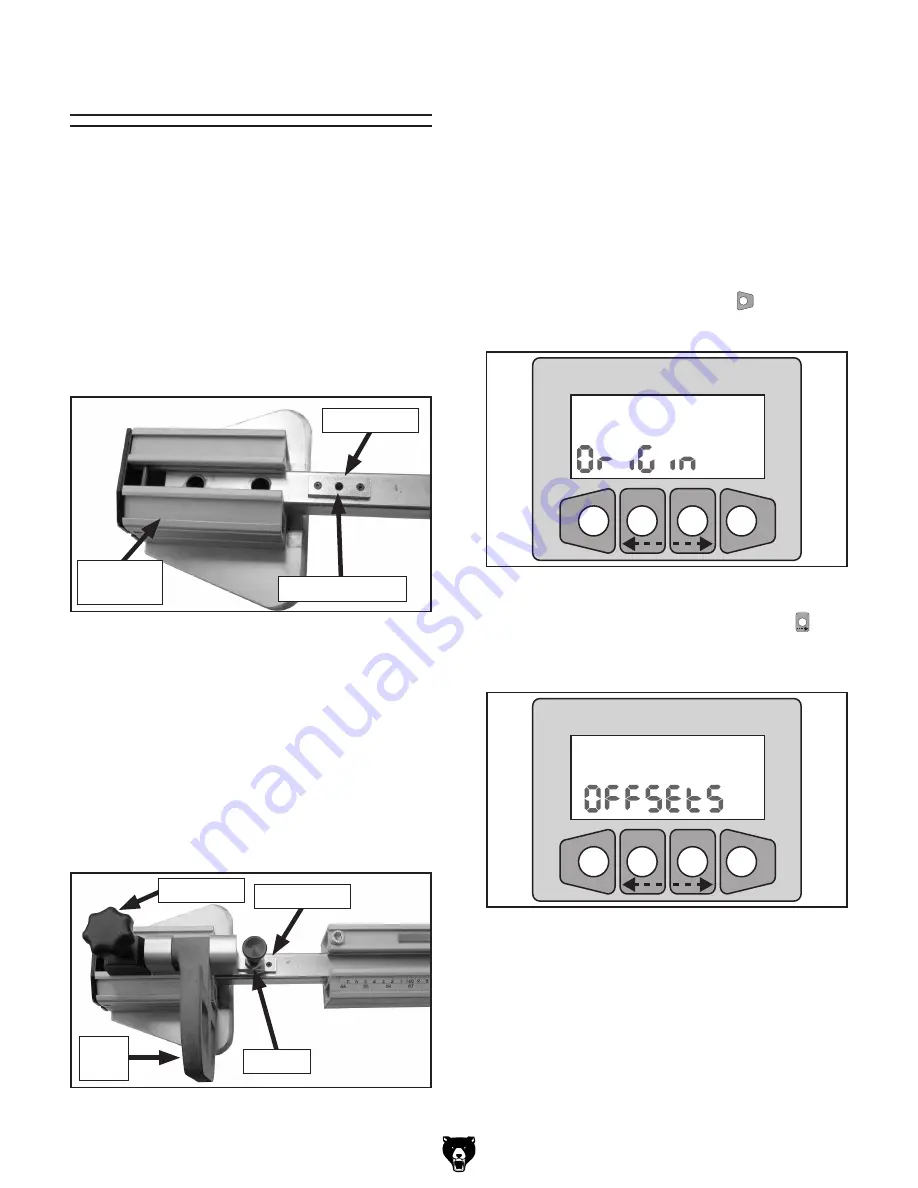

Figure 38.

Origin screen.

2.

Press the right arrow key (mm/inch

�������

key)

twice until the display shows the word

"Offsets" as in

Figure 39

.

���

������� �������

�

�����

���

Figure 39.

Offsets screen

It works like this: the stopper in the digital stop

block is dropped into the home origin block. This

locks the digital stop block to the sliding plate

inside the fence. The second stop block is then

moved to one of the two origin blocks and locked

using a similar stopper (

Figure 37

). The display

on the digital stop block is then changed to one of

the "ORG" settings, resulting in the display read-

ing the position of the second stop block, rather

than the position of the digital stop block.

Figure 36.

Origin block near fence extension.

Origin Block

Hole for Stopper

Fence

Extension

Figure 37.

Second stop block engaged in origin

block near fence extension.

Origin Block

Stopper

Lock Knob

Basically, the display shows the dimension of the

second stop block because it adds a pre-pro-

grammed offset distance from one origin block to

the other.

Aside from the two origin block offsets, two addi-

tional offsets can be programmed in the controller

to be used with jigs or measurement blocks.

Entering Offset Values

1.

Press and hold the F/ENTER

�

�����

key until the

"Origin" screen appears as in

Figure 38

.

Stop

Block