-4-

G0620 Main Control Panel

Quick Start

Manual Adjustments

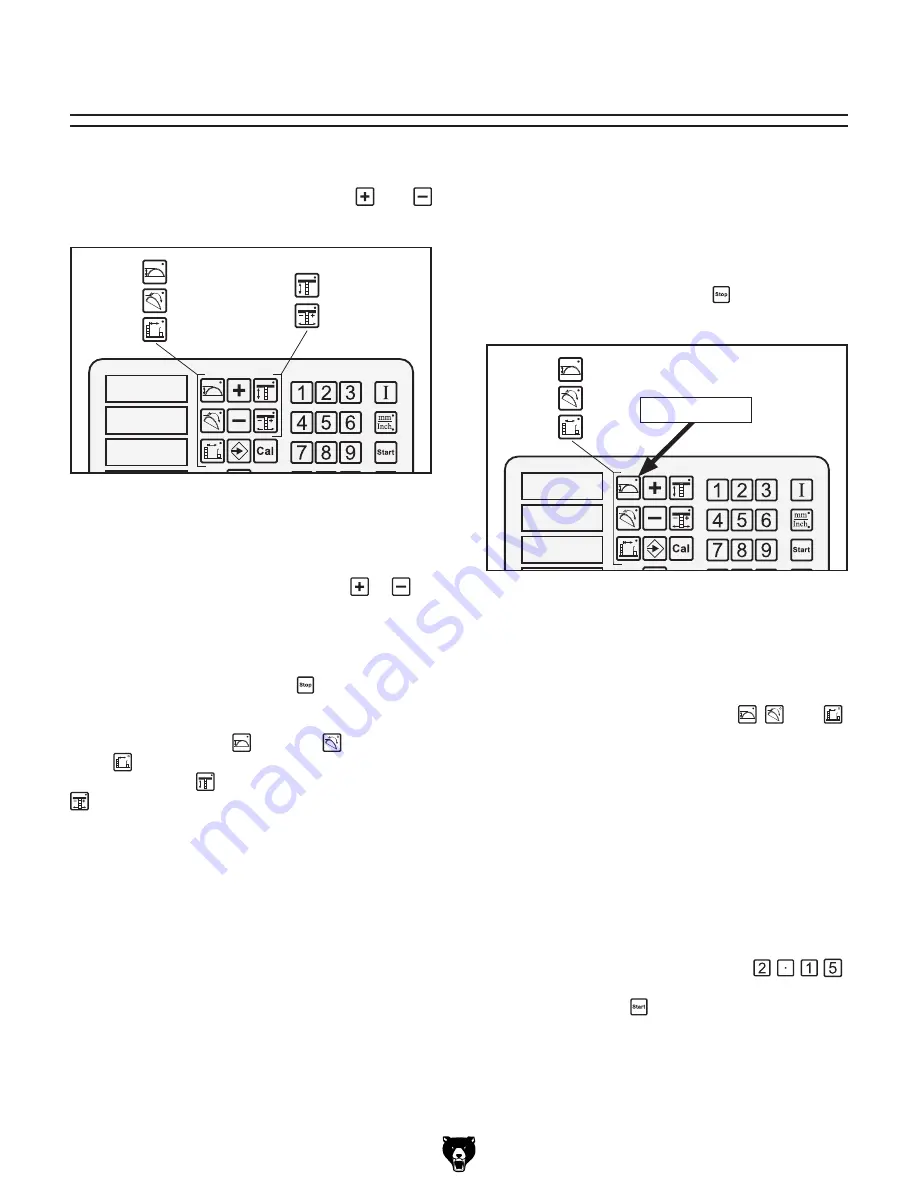

The components controlled by the keys in

Figure

2

can be manually adjusted using the

and

keys.

�

�

�

����

Figure 2.

Controls keys capable of manual

operation.

To manually adjust any of these components,

press one of the control keys shown in

Figure 2

so its indicator light shines, then press or as

desired to manually position the related control.

When finished, press the control key again so its

indicator light stops shining.

Note:

You can press the Stop

key at any time

to cancel the operation.

Only the blade height , table tilt , and cutting

width controls allow numerical input. The scor-

ing blade height

and scoring blade alignment

controls must be adjusted by eye or by an

independent guide, such as a straightedge.

Typically manual controls are used when math-

ematical adjustments are not practical, such as

those adjustments done by eye or when setting

the components to a marked workpiece.

Numerical Input Adjustments

The components controlled by the keys in

Figure

3

can be controlled by numerical input and

will automatically adjust to the dimension you

entered. For more details on controlling any one

component, refer to the

Section 3: Operations

.

Note:

You can press the Stop

key at any time

to cancel the operation.

�

�

�

����

Figure 3.

Controls capable of being moved by

numerical input.

To move the components with numerical

input:

1.

Press the desired control key ( , , and )

for the component that you want to move.

The indicator light on the key (

Figure 3

)

shines to tell you that the control panel is

ready to accept your input.

2.

Enter your input with the number keypad.

As you press the keys, the display will flash

the numbers you have entered.

Example:

If your input is 2.15", then you

would press the following keys: .

3.

Press the Start key and the component will

move to where it is directed by your input.

Indicator Light