G0620 Main Control Panel

-9-

Combining

Adjustment Entries

The controller has the ability to combine numeri-

cal input entries of the blade height, blade tilt, and

rip fence without closing the input cycle after each

entry. This is typically the most efficient way to set

up a new cut.

To enter multiple entries, follow the same steps

for numerical adjustments with each control, but

wait to press the Start

key until after the last

control input has been entered.

Example:

If you want to set up a cut with a blade

height of 2.25", a blade tilt of 22.5°, and a cut-

ting width of 18.25", you would do the following

steps:

1.

Press the blade height key.

The indicator light on the blade height key

shines to show that the control panel is ready

to accept input.

2.

Use the number keys to enter the blade

height (

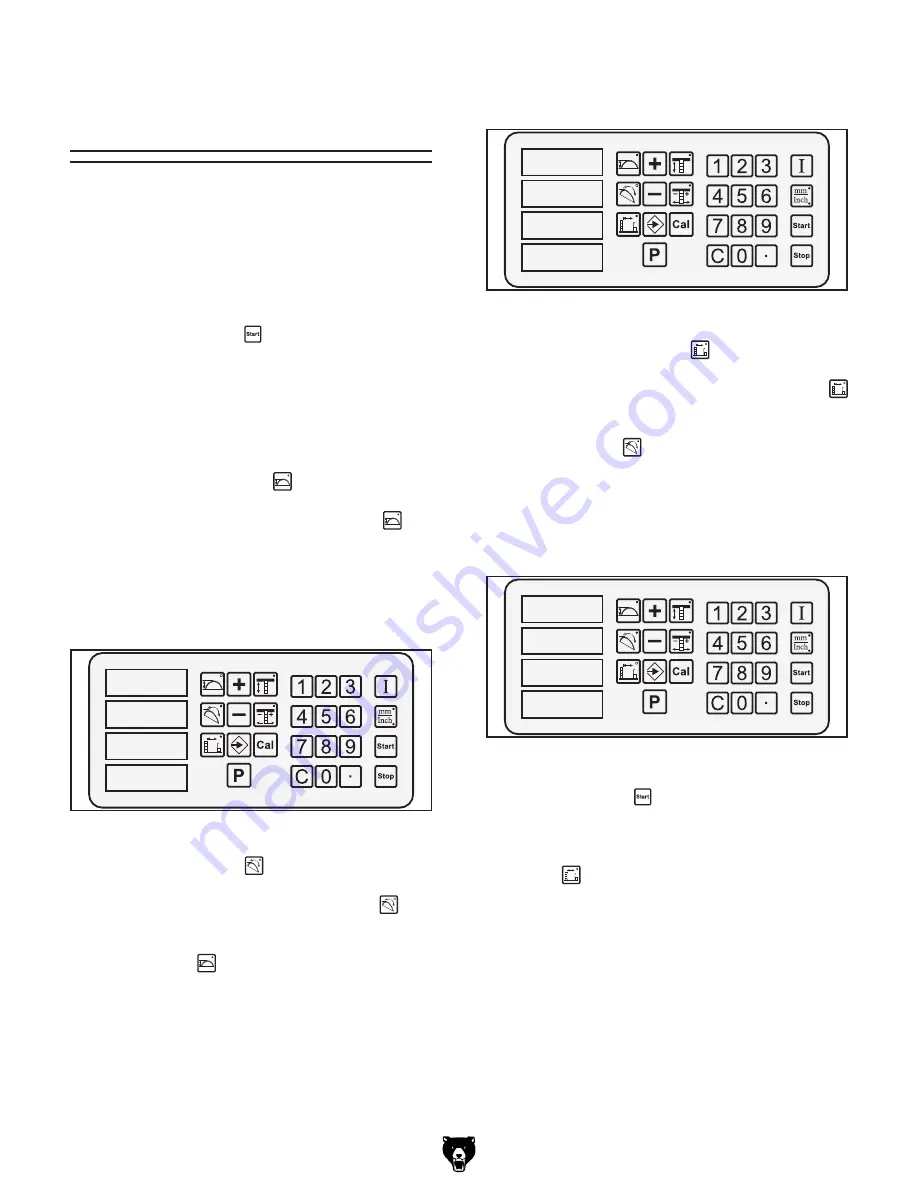

Figure 12

).

����

�

�

����

Figure 12.

First entry.

����

����

�

����

Figure 13.

Second entry.

����

����

�����

����

Figure 14.

Third entry.

3.

Press the blade tilt key.

The indicator light on the blade tilt

key

shines to show that the control panel is ready

to accept input. The indicator light on the

blade height key no longer shines, but the

numbers previously entered still flash.

5.

Press the cutting width key.

The indicator light on the cutting width

key shines to show that the control panel is

ready to accept input. The indicator light on

the blade tilt

key no longer shines, but

both numbers previously entered continue to

flash.

6.

Use the number keys to enter the cutting

width (

Figure 14

).

7.

Press the Start key.

All components will move to their respective

positions and the indicator light on the cutting

width key will stop shining.

4.

Use the number keys to enter in the blade

angle (

Figure 13

).