-14-

G0620 Main Control Panel

Rip Fence Cutting

Width Calibration

Performing this procedure ensures that cutting

width from the rip fence accurately matches what

is shown in the digital display.

We recommend calibrating the blade height every

time you change the blade.

The calibration is a simple procedure that only

takes minutes. For precise results, use a pair of

calipers to take the measurements noted below.

Note:

You can stop the calibration process at any

time by pressing the Stop key.

Tools Needed

Qty

Calipers (Dial or Digital) .................................... 1

To calibrate the rip fence cutting width:

1.

Raise the blade up to 2.25" high, tilt the blade

to 0.0, and move the rip fence 4" away from

the blade.

2.

Measure the distance from the blade to the

fence by either making a test cut and measur-

ing the result or by using a pair of calipers.

—If using a test cut to measure this dis-

tance, make the test cut, measure your cut

workpiece, then proceed to

Step 7

.

—If using calipers to make your measure-

ment, proceed to

Step 3

.

3.

Completely close your calipers and make

sure they are at 0.000" (if not, zero them

now).

4.

DISCONNECT SAW FROM POWER!

5.

Close the calipers on one of the carbide teeth

on the main blade, then zero the calipers out.

(This will automatically subtract the blade

thickness when measuring the cutting width

in the next step.)

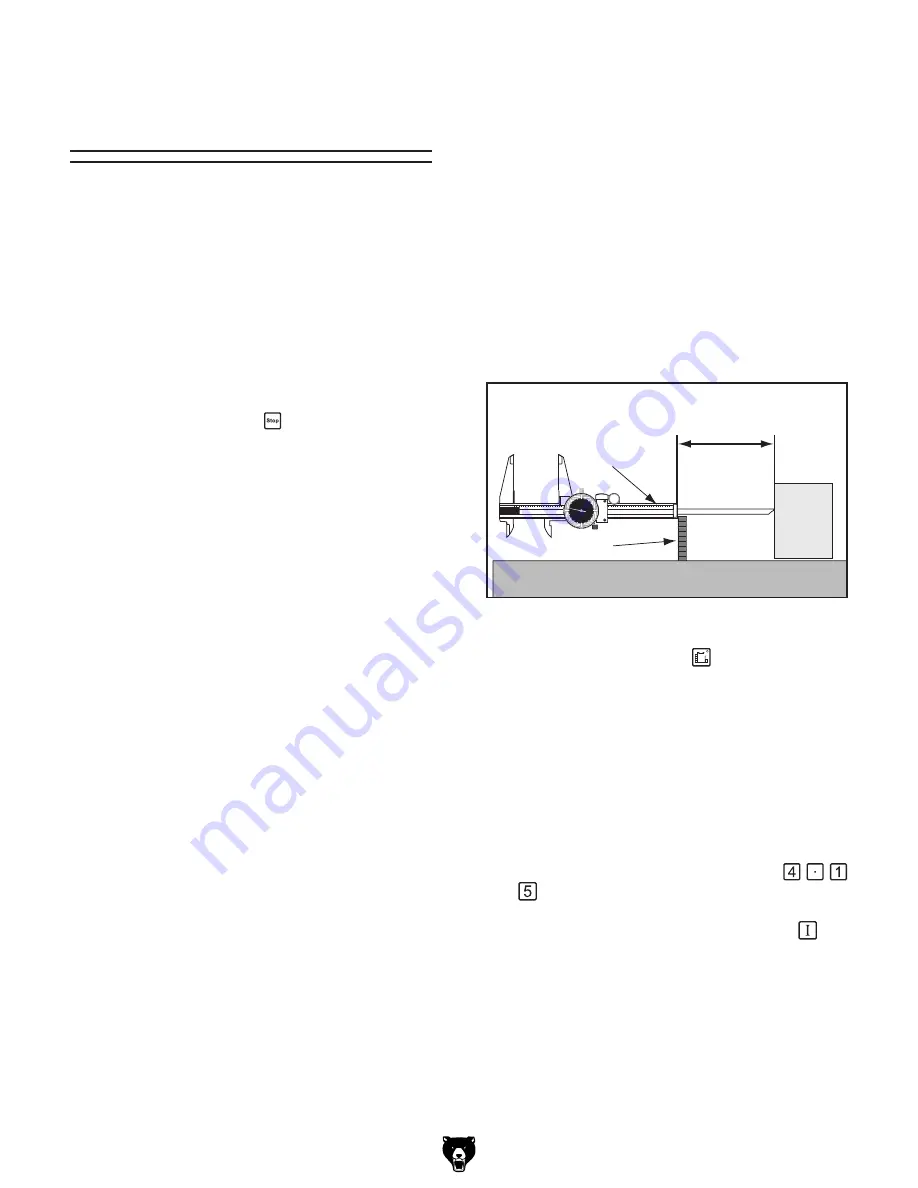

6.

Place the bottom of the calipers on one of

the carbide teeth and extend the caliper mea-

surement bar to touch the rip fence, as shown

in

Figure 26

, then lock the calipers in place

and read the measurement.

—If the measurement on the calipers reads

0.02" or less away from 4", then the rip

fence cutting width calibration is already

correct.

—If the measurement on the calipers reads

more than 0.02" away from 4", then the rip

fence cutting width must be recalibrated.

Continue to the next step.

�

�

��

��

��

��

��

��

��

��

��

�����

��������

��������������

�����������������������

�����

�����

Figure 26.

Measuring cutting width with calipers.

7.

Press the cutting width

key. The indicator

light on the key shines to show that the con-

trol panel is ready to accept input.

8.

Enter your measurement from

Step 5

with

the keypad.

As you press the keys, the display will flash

the numbers you have entered.

For Example:

If you measured 4.15", then

you would press the following keys:

.

9.

Press and hold the input confirmation

key

until the display stops flashing. The new set-

ting now remains on the display.