-20-

G0620 Main Control Panel

3.

Press the F/ENTER

�

�����

key.

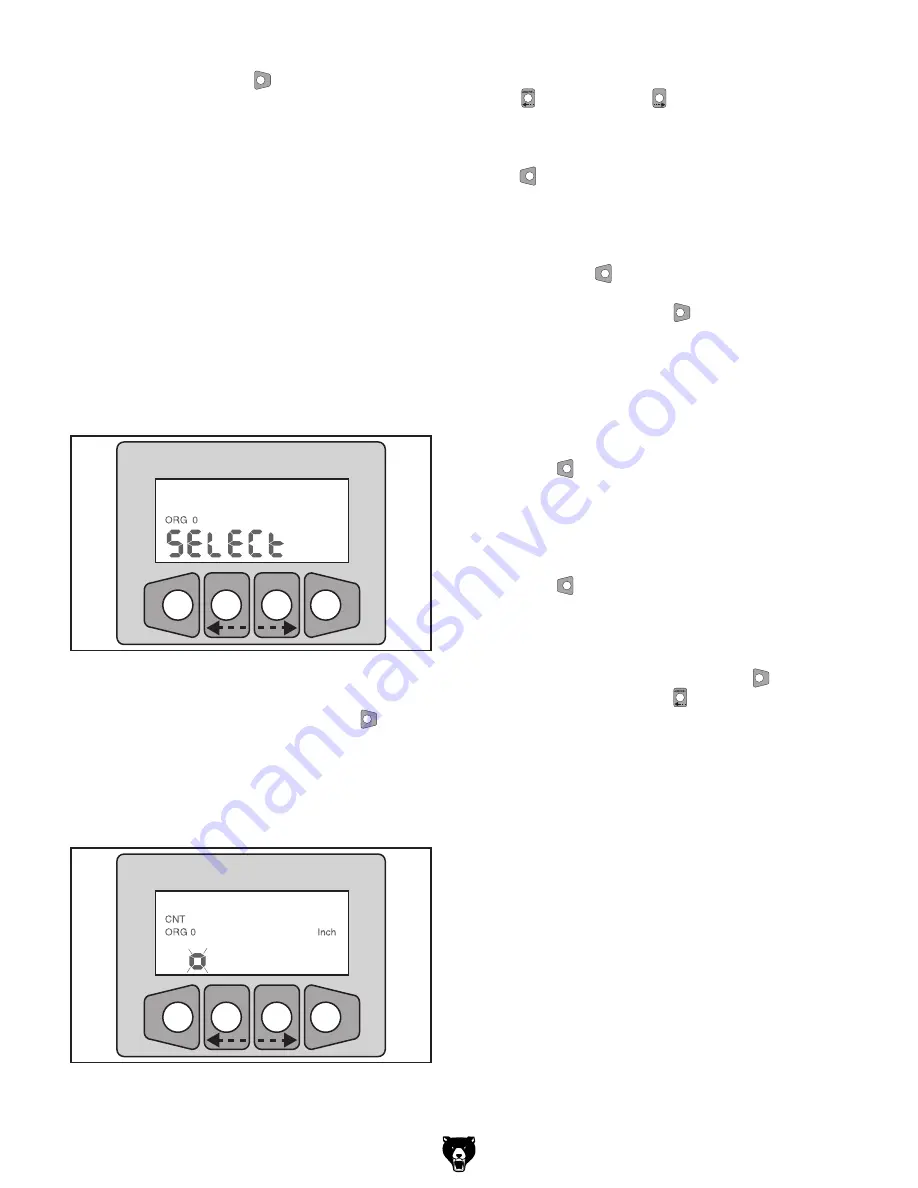

"Select" appears on the display (

Figure 40

)

with "ORG" and a number next to it, prompt-

ing you to select which ORG to program.

Note:

When programming "ORG 0," put the

digital stop block stopper in the home origin

block (the closest one to the blade) and put

the second stop block stopper in the ori-

gin block closest to the home origin block.

Measure the distance from the usable face

of the digital stop block to the usable face

of the second stop block, and program that

distance into the controller. When program-

ming "ORG 1," move the second stop block to

the origin block near the fence extension and

repeat.

���

������� �������

�

�����

���

Figure 40.

ORG select screen.

4.

Use the arrow keys to select which ORG to

program, then press the F/ENTER

�

�����

key.

The display changes to an entry screen with

a flashing "0", as shown in

Figure 41

. (Due

to resolution settings, the number of zeros

displayed may not match the figure exactly.)

���

������� �������

�

�����

���

��������

Figure 41.

Controller ready to enter a value for

ORG 0.

5.

Use the left and right arrows on the ABS/REL

and mm/inch

�������

keys to select the digit

you want to modify.

Modify the digits by pressing the CLR/SET

���

���

key when the desired digit is blinking.

The smaller 0 at the far left of the number rep-

resents a positive value, but can be modified

to a negative value if desired by pressing the

CLR/SET

���

���

key when it is blinking.

6.

Press the F/ENTER

�

�����

key to save the cur-

rent number in the controller.

The display will go back to the "Select"

screen. From this screen, you can enter addi-

tional cutoff values by repeating

Steps 4-5

.

7.

To exit the "Select" screen, press the CLR/

SET

���

���

key.

The display will go back to the "Offsets"

screen.

8.

To exit the "Offsets" screen, press the CLR/

SET

���

���

key.

Activating Stored Offsets

1.

Press and hold the F/ENTER

�

�����

key, then

press the ABS/REL key to cycle through

the ORG numbers.

The offset value is automatically applied to

the current value displayed when the related

ORG number is selected.