G0620 Main Control Panel

-11-

����

���

�����

�

�����

��

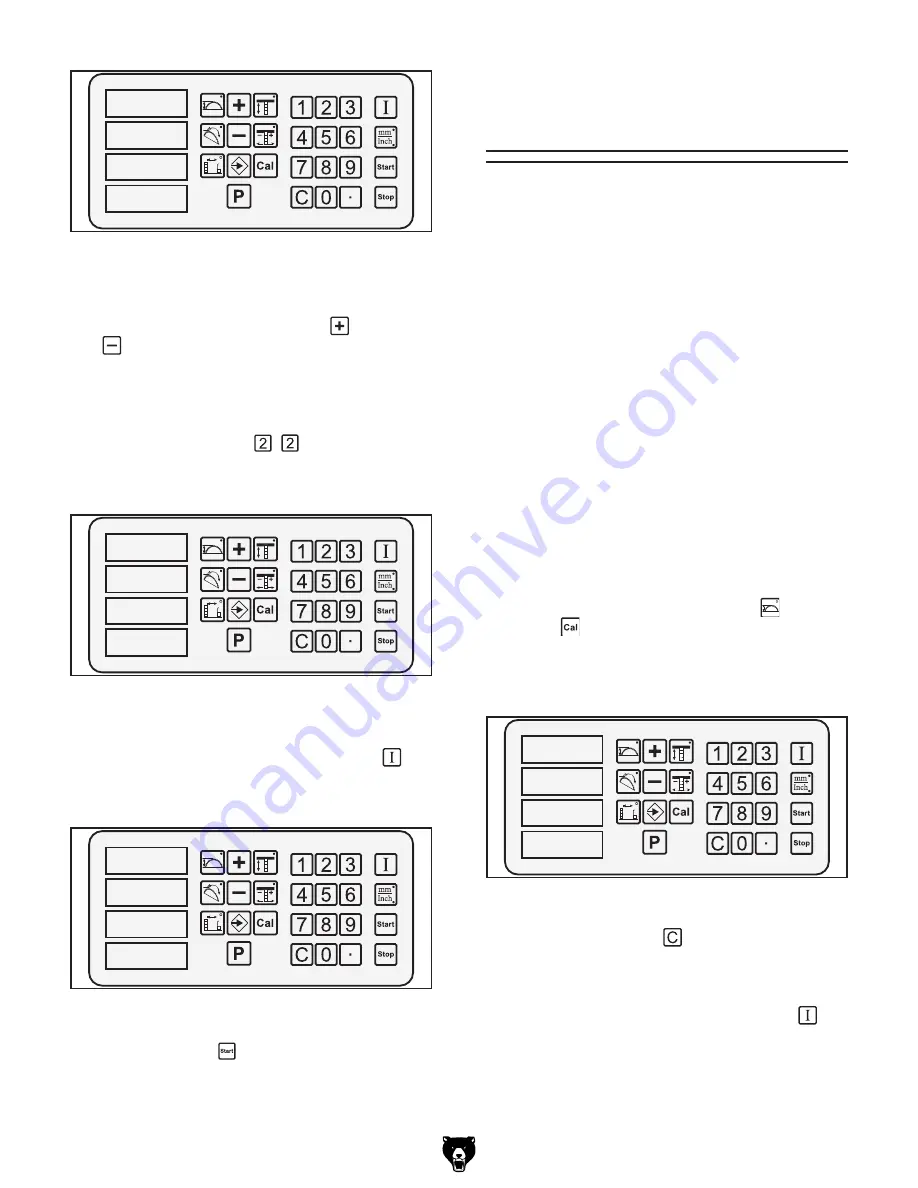

Figure 19.

"P" displayed on control panel to

indicate system is ready to recall saved settings.

2.

Type in the number of the saved setting you

want to recall, or use the plus

and minus

keys to scroll through each saved setting

to find the one you want.

Example:

To recall the setting saved in the

example of the previous subsection, press

the following keys:

. The display will

look similar to

Figure 20

, showing the dimen-

sions of each of the three components.

����

����

�����

�

�����

��

Figure 20.

Saved setting 22 entered into the

recall display.

4.

Press and hold the input confirmation

key

until the dimensions start flashing, as shown

in

Figure 21

.

����

����

�����

����

Figure 21.

Recalled dimensions flashing.

5.

Press the Start key.

All components will move to their respective

positions

Blade Diameter

Calibration

The exact dimensions of a blade can be pro-

grammed into the control panel, so the blade

height controls will not be skewed by blades of

different sizes. We recommend performing this

calibration procedure every time you change

blades, especially if changing between 12" and

14" blades.

Tools Needed

Qty

Measuring Tape ................................................ 1

To calibrate the control panel for your exact

blade diameter:

1.

DISCONNECT SAW FROM POWER.

2.

Remove blade, measure its diameter, then

reinstall it.

3.

Connect saw to power, reset stop button, turn

ON

the control panel, then turn it

OFF

.

4.

Press and hold the blade height

and cali-

brate keys at the same time, then turn the

control panel back

ON

. After a few seconds,

the current blade diameter will flash and the

display will look similar to

Figure 22

.

5.

Press the clear key , then type in the exact

dimensions of your blade with the number

keys.

6.

Press and hold the input confirmation

key

until the display changes to the normal view.

�����

Figure 22.

Blade diameter display.