CS610-UM-251-9370

13-11

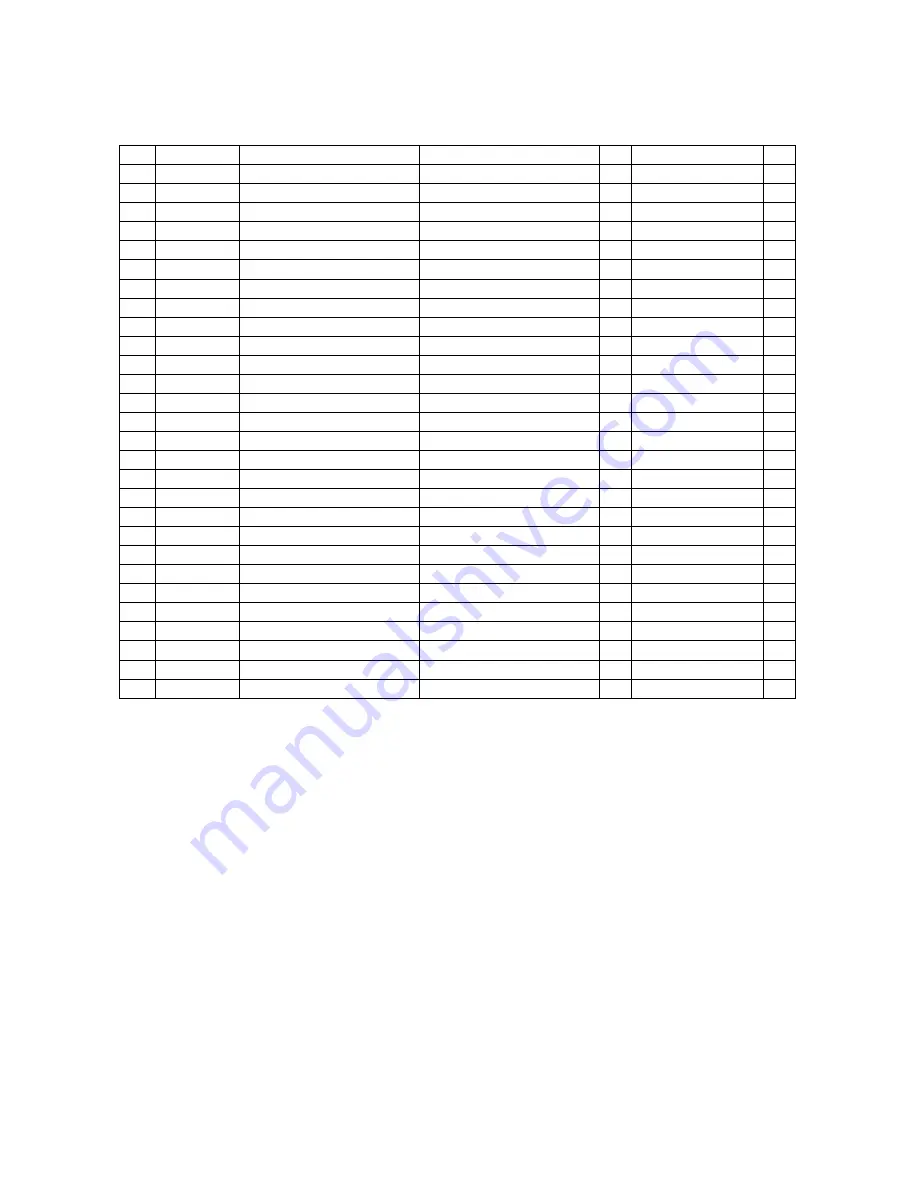

13. PARTS LIST

13.7 Cables

No.

Part No.

Part name

Description

Q'ty

Remarks

SR

1

694500901 3SB-2C-13A

DCB to PB (J15-J5)

1

C

2

694500792 3SB-2C-2B

DCB to PB (J12-J2)

1

C

3

694500833 3SB-2C-6C

DCB to PB (J13-J3)

1

C

4

694500841 3SB-2C-7A

Switching Power Supply

1

C

5

694501121 CA4501120A

PB to LAN board

1

C

6

694501111 CA4501110A

LAN Board to PCB (J401)

1

C

7

694501102 CA4501100B

LAN Board to PCB (J901)

1

C

8

694450110 FPC Cable CS20

CIS Flexible Cable

5

A

9

694500784 3SB-2C-1D

CIS Board Power Supply

5

C

10

694500864 3SB-2C-9D

CIS Board to DCB Cable (J20)

1

C

11

694500942 3SB-2C-17B

CIS Board to DCB Cable (J21)

1

C

12

694500952 3SB-2C-18B

CIS Board to DCB Cable (J22)

1

C

13

694500962 3SB-2C-19B

CIS Board to DCB Cable (J23)

1

C

14

694500972 3SB-2C-20B

CIS Board to DCB Cable (J24)

1

C

15

694505340 CA450534

Control Panel Relay Cable

1

C

16

694505110 CA450511

Control Panel Relay Cable

1

C

17

694505311 CA450531A

Control Panel Relay to Motor Control Board

1

C

18

694500873 3SB-2C-10

Front & Rear Sensor

1

C

19

694505060 CA450506

Motor Control Board to Sensor Relay Board

1

C

20

694505071 CA450507A

Motor Control Board to High Limit Sensor

1

C

21

694505081 CA450508A

Motor Control Board to Low Limit Sensor

1

C

22

694505090 CA450509

Motor Control Board to DCB

1

C

23

694505000 CA450500

Sensor Relay Board to Thickness Sensor

1

C

24

694505012 CA450501B

Sensor Relay Board to Safety Sensor L

1

C

25

694505021 CA450502A

Sensor Relay Board to Cover Sensor R

1

C

26

694505030 CA450503

Sensor Relay Board to Cover Sensor L

1

C

27

694505041 CA450504A

Sensor Relay Board to Safety Sensor R

1

C

28

694505060 3SB-2C-31

PB to Stepping Motor

1

C

Summary of Contents for CS610-11eN

Page 1: ...COLORIMAGESCANNER SERVICE MANUAL CS610 SERIES CS610 UM251 02 9370...

Page 2: ......

Page 42: ......

Page 44: ......

Page 118: ......

Page 120: ......

Page 128: ...13 PARTS LIST CS610 UM 251 9370 13 8 CIS Unit 6 4 2 11 9 10 12 8 1 3 5 7...