Programming Site Data

2-27

September 2004

Selecting Error Handling -

ERROR (cont.)

9.

Press [

X

] to activate or deactivate two-path error handling and

press

[ENTER]

. The

2PATH ERROR HAND

option is intended for

applications where two sets of transducers are installed in the

same location in the same pipe to improve accuracy and the meter

is operated in

AVE

mode. With this function enabled, the Model

AT868 performs error handling only if both channels/paths are in

error. If this function is disabled, error handling occurs when

either channel/path goes into error.

Specific responses of the display and the totalizer to the two-path

error handling option available at the above prompt are listed in

Table 2-6 below.

Procedure Options

After completing the above steps, the user program returns to the

Global I/O

window. Do one of the following:

•

To continue regular programming, refer to Appendix A,

, to navigate to the desired menu.

•

To leave the user program, press

[ESC]

four times.

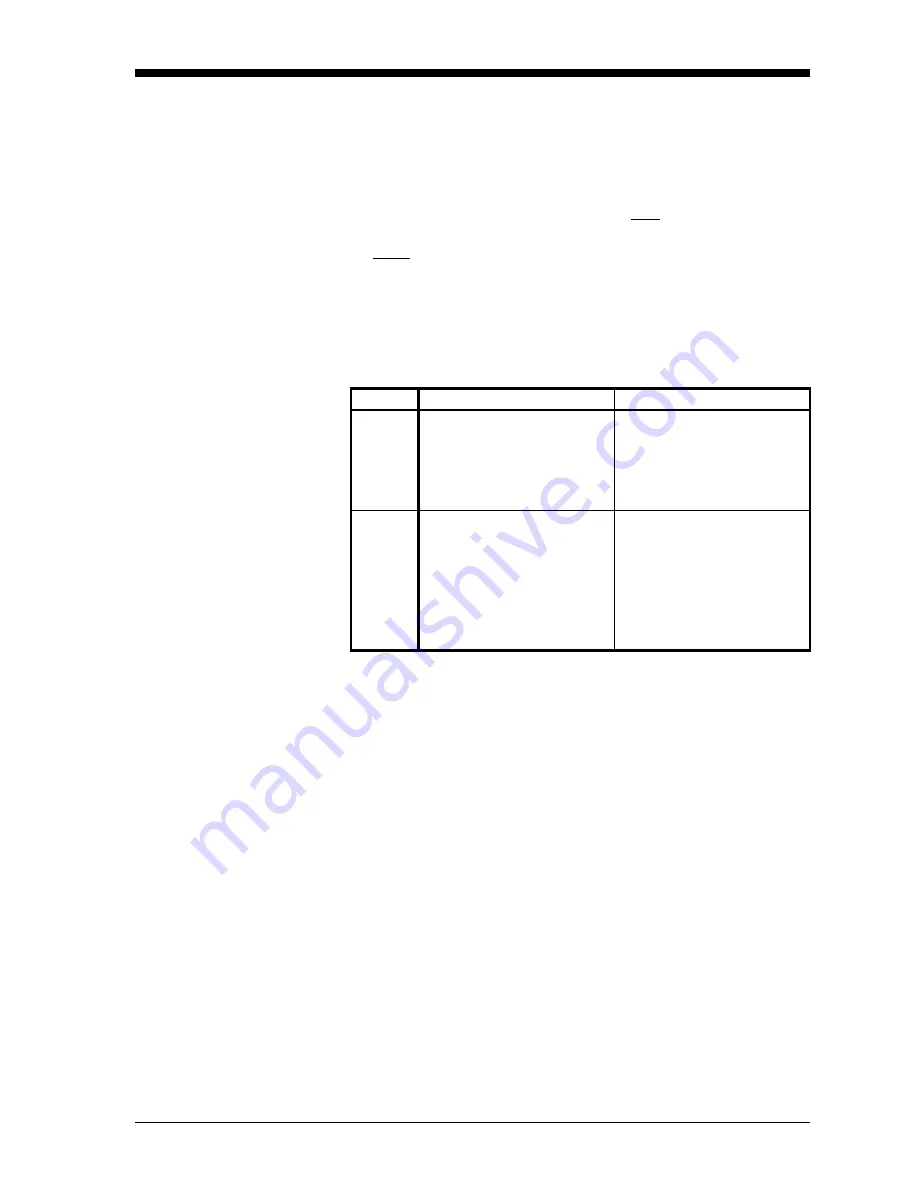

Table 2-6: 2-Path Error Response Options

Option

Display Response

Totalizer Response

NO

Displays the average of

channels/paths 1 and 2,

regardless of the error state

of either channel/path.

Outputs the average of

channels/paths 1 and 2

totals, regardless of the

error state of either

channel/path.

YES

1. If one channel/path is in

error, the other channel/

path’s value is displayed

as the average.

2. If both channels/paths

are in error, the last

average reading is held.

1. If one channel/path is in

error, totalizing

continues.

2. If both channels/paths

are in error, totalizing

stops.

Summary of Contents for AquaTrans AT868

Page 8: ...Chapter 1 ...

Page 24: ...Chapter 2 ...

Page 60: ...Chapter 3 ...

Page 66: ...Chapter 4 ...

Page 72: ...Chapter 5 ...

Page 77: ...Chapter 6 ...

Page 88: ...Chapter 7 ...

Page 98: ...Chapter 8 ...

Page 106: ...Appendix A ...

Page 112: ...Appendix B ...

Page 113: ...CE Mark Compliance Introduction B 1 EMC Compliance B 1 LVD Compliance B 2 ...

Page 116: ...Appendix C ...

Page 117: ...Data Records Site Data C 1 ...

Page 122: ...Appendix D ...

Page 123: ...Measuring P and L Dimensions Measuring P and L D 1 ...

Page 126: ...Appendix E ...

Page 127: ...Service Record Introduction E 1 Data Entry E 1 Diagnostic Parameters E 3 ...

Page 131: ...Appendix F ...