Section 1

1-28

© Copyright 2009 GBC. All rights reserved.

Advanced Punch Service Manual

1.4.16 Bypass Paper Path Inspection and Cleaning

Maintenance Schedule

Clean every 750K cycles.

Replace every 4000K cycles. See Page 4-8.

Procedure

•

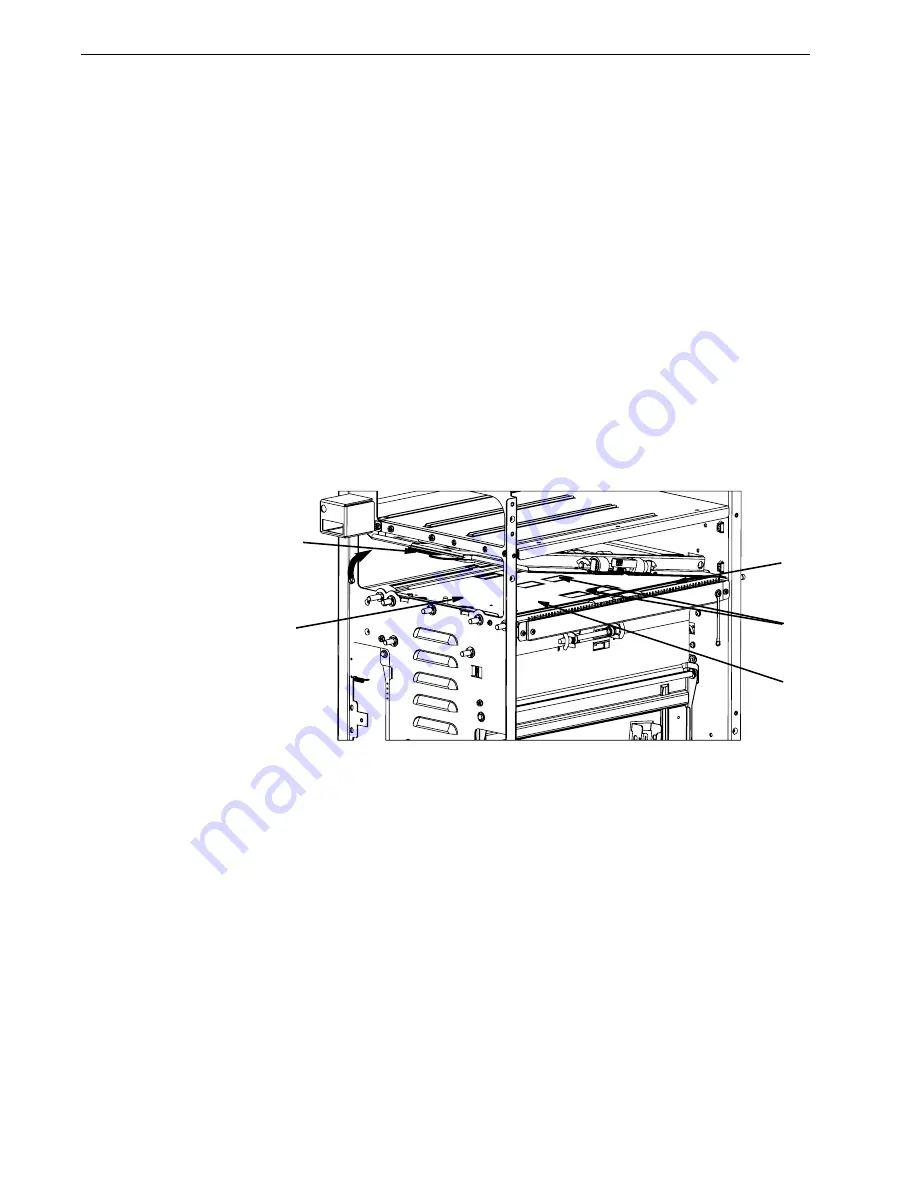

Inspect the Bypass panel [1], rollers [2], and entrance guide [3] for wear,

damage, and obstructions.

•

Inspect the rollers for wear patterns or groves. The surface should be rough

and even. Make sure the rollers are clean. Clean rollers with a soft cloth and

alcohol. See also “Idler Roller Inspection and Cleaning” on page 1-20 and

“Drive Roller Inspection and Cleaning” on page 1-24.

•

Raise the panel and ensure the magnet holds it in open [4]. Inspect the path

for obstructions. Clean as needed.

•

Close the panel and check that it is flat and that paper will pass under it.

•

Ensure the bypass diverter moves freely and returns to the bypass position.

Figure 1.16 Bypass Path Inspection. Shown With Bypass Panel Raised.

[4]

[1]

[2]

[5]

[3]

Summary of Contents for AdvancedPunch

Page 1: ...Document 7712571 Rev C1 23 08 2013 AdvancedPunch Technical Service Manual ...

Page 143: ...Section 5 5 4 Copyright 2009 GBC All rights reserved Advanced Punch Service Manual ...

Page 144: ...Parts List Advanced Punch Service Manual Copyright 2009 GBC All rights reserved 5 5 ...

Page 149: ...Section 5 5 10 Copyright 2009 GBC All rights reserved Advanced Punch Service Manual ...

Page 150: ...Parts List Advanced Punch Service Manual Copyright 2009 GBC All rights reserved 5 11 ...

Page 199: ...Section 8 8 4 Copyright 2009 GBC All rights reserved Advanced Punch Service Manual 2 1 ...

Page 201: ...Section 8 8 6 Copyright 2009 GBC All rights reserved Advanced Punch Service Manual 2 1 2 1 2x ...