Appendix

Quick reference

4

1

3

2

5

Fronius International GmbH, www

.fronius.com

Keylock

Important!

If the keylock is activated, only the

parameter settings can be retrieved, as well

as any assigned “Save“ button provided that

an assigned “Save“ button was selected when

the keylock was enabled.

-

press and hold

- press

- release

activate / deactivate:

activated: „CLO | SEd“ display

deactivated: „OP

| En“ display

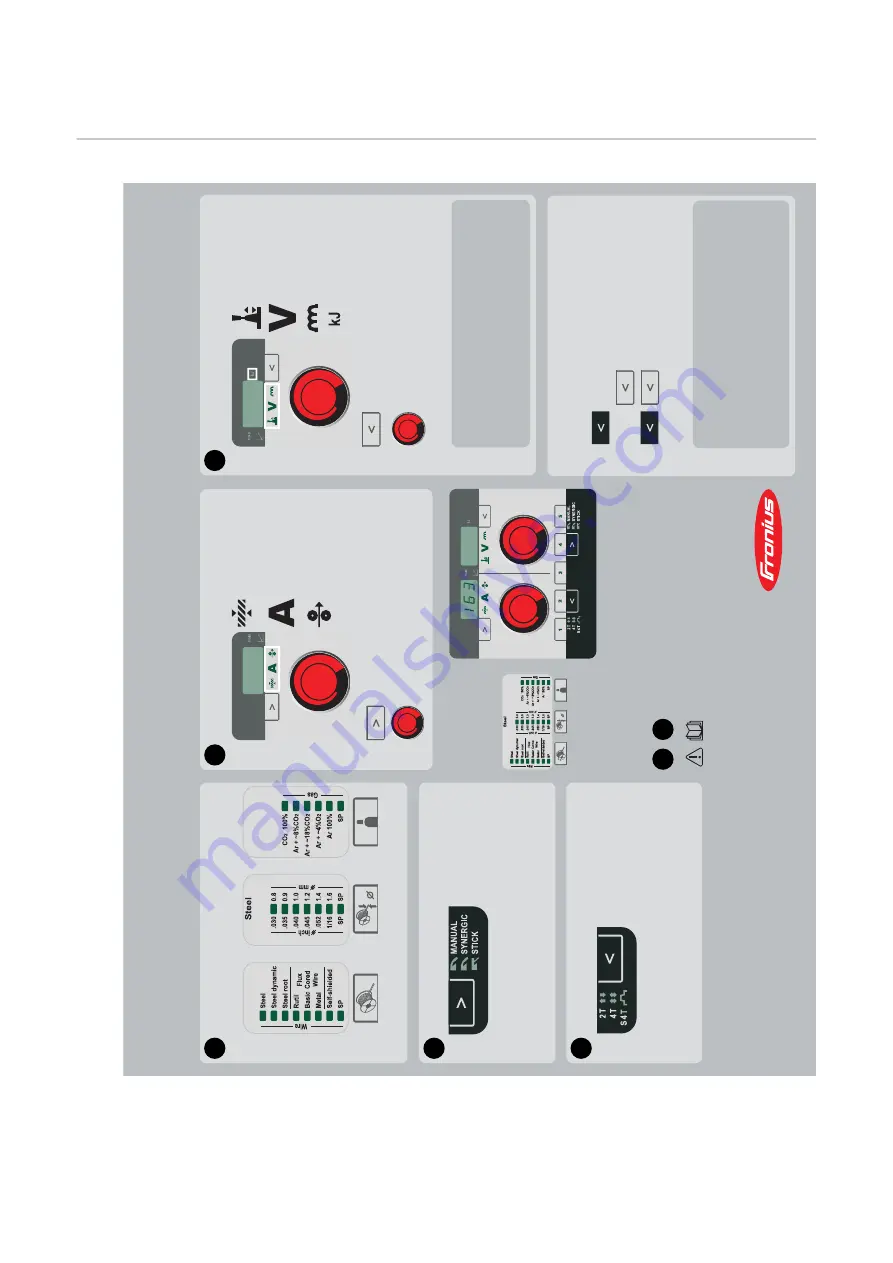

Quick Reference: English

Setting the welding power

Selecting the fi

ller metal and

shielding gas

2 T

2-step

mode

4 T

4-step

mode

S 4

T

Special 4-step mode

Selecting the process

Setting the mode

MANUAL

MIG/MAG standard manual

SYNERGIC Standard

synergic

STICK

Manual metal arc welding

Correcting parameters

Important

If external system components

are connected, some parameters can be

modifi

ed on those components.

The power

source control panel is only for display

purposes.

01/2013

Start-up sequence

Follow operating instructions

-

1

5

T

ransSteel Synergic

SP

... Special Program

-

select desired parameter

- set desired parameter

Sheet thickness

W

elding current

Wire feed speed

Arc length

correction

W

elding voltage

Dynamic

-

select desired parameter

- set desired parameter

Real Energy Input

114

Summary of Contents for TransSteel 2700c

Page 2: ......

Page 18: ...18...

Page 19: ...General information 19...

Page 20: ...20...

Page 26: ...VRD is active again The output voltage is limited to 35 V once more 26...

Page 27: ...Control elements and connections 27...

Page 28: ...28...

Page 37: ...Installation and commissioning 37...

Page 38: ...38...

Page 62: ...62...

Page 63: ...Welding 63...

Page 64: ...64...

Page 78: ...Number 2 Number 3 Number 4 Number 5 78...

Page 79: ...Setup settings 79...

Page 80: ...80...

Page 91: ...10 Fit the gas nozzle back onto the welding torch 91 EN...

Page 93: ...Troubleshooting and maintenance 93...

Page 94: ...94...