Contact your tire manufacturer/supplier to deter-

mine the rolling resistance of the originally in-

stalled tires. Visit

for

additional information and resources.

3.

Check tire inflation.

For inflation pressures and maximum loads, see

the tire manufacturer’s guidelines. Inflate the tires

to the applicable pressures if needed.

If a tire has been run flat or under-inflated, check

the wheel and tire for damage before adding air.

Keep compressed air reservoirs and lines dry

during tire inflation. Use well-maintained inline

moisture traps and service them regularly.

WARNING

Do not operate the vehicle with underinflated or

overinflated tires. Incorrect inflation can stress

the tires and make the tires and rims more sus-

ceptible to damage, possibly leading to rim or

tire failure and loss of vehicle control, resulting

in serious personal injury or death.

NOTICE

A weekly pressure loss of 4 psi (28 kPa) or more

in a tire may indicate damage. The tire should be

inspected and, if necessary, repaired or replaced

by a qualified tire service facility.

IMPORTANT: The load and cold inflation pres-

sure must not exceed the rim or wheel manu-

facturer’s recommendations, even though the

tire may be approved for a higher load inflation.

Consult the rim or wheel manufacturer for the

correct tire inflation pressure for the vehicle

load.

4.

Examine each rim and wheel component.

4.1

Remove all dirt and debris from the as-

sembly. Rust streaks or metal build-up

around stud holes, or out-of-round or worn

stud holes, may be caused by loose wheel

nuts.

WARNING

Have any worn or damaged wheel components

replaced by a qualified person using the wheel

manufacturer’s instructions and the wheel indus-

try’s standard safety precautions and equipment.

Otherwise a vehicle or workshop accident could

occur, possibly resulting in serious personal in-

jury or death.

4.2

Inspect for broken, cracked, badly worn,

bent, rusty, or sprung rings and rims.

NOTICE

Use the recommended torque values and follow

the proper tightening sequence. Insufficient

wheel nut torque can cause wheel shimmy, re-

sulting in wheel damage, stud breakage, and ex-

treme tire tread wear. Excessive wheel nut torque

can break studs, damage threads, and crack

discs in the stud hole area.

4.3

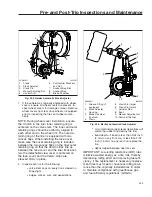

Make sure all wheel nuts are tightened. If

tightening is necessary, use the tightening

pattern in

to initially tighten the

flange nuts to 50 to 100 lbf·ft (68 to 136

N·m). Then tighten the flange nuts to 450

to 500 lbf·ft (610 to 678 N·m).

5.

Inspect the outboard side of all wheel hubs and

the hub oil seal area on the inboard side of each

wheel for signs of oil leakage. If any oil is found

on wheel and tire or brake components, remove

the vehicle from service until the leak has been

fixed.

If needed, fill the hubs to the level indicated on

the hub cap. See

Group 35

of the

New Casca-

dia Maintenance Manual

for recommended lubri-

cants.

f400268

1

10

8

6

4

9

2

7

5

3

04/30/2007

Fig. 23.4, Tightening Pattern, 10-Hole Wheels

Pre- and Post-Trip Inspections and Maintenance

23.3

Summary of Contents for NEW CASCADIA 2016

Page 1: ... NEW CASCADIA Driver s Manual Part Number STI 500 Publication Number STI 500 8 ...

Page 5: ......

Page 11: ......

Page 38: ...f611444 10 31 2016 Fig 3 23 Sample Alert Messages Instruments 3 20 ...

Page 39: ......

Page 93: ......

Page 94: ...8 Cab and Sleeper Features Windows 8 1 Mirrors 8 1 Cab Amenities 8 1 Sleeper Amenities 8 2 ...

Page 99: ......

Page 125: ......

Page 134: ...14 Steering System Power Steering System 14 1 ...

Page 145: ......

Page 146: ...16 Manual Transmissions and Clutch Eaton Fuller Manual Transmissions 16 1 Clutch 16 1 ...

Page 149: ......

Page 150: ...17 Drive Axles Interaxle Lock Tandem Axles 17 1 Driver Controlled Differential Lock DCDL 17 2 ...

Page 164: ...19 Trailer Couplings Holland Trailer Coupling 19 1 ...

Page 177: ......

Page 191: ......

Page 198: ...25 Specifications Fluids and Lubricants 25 1 ...