67

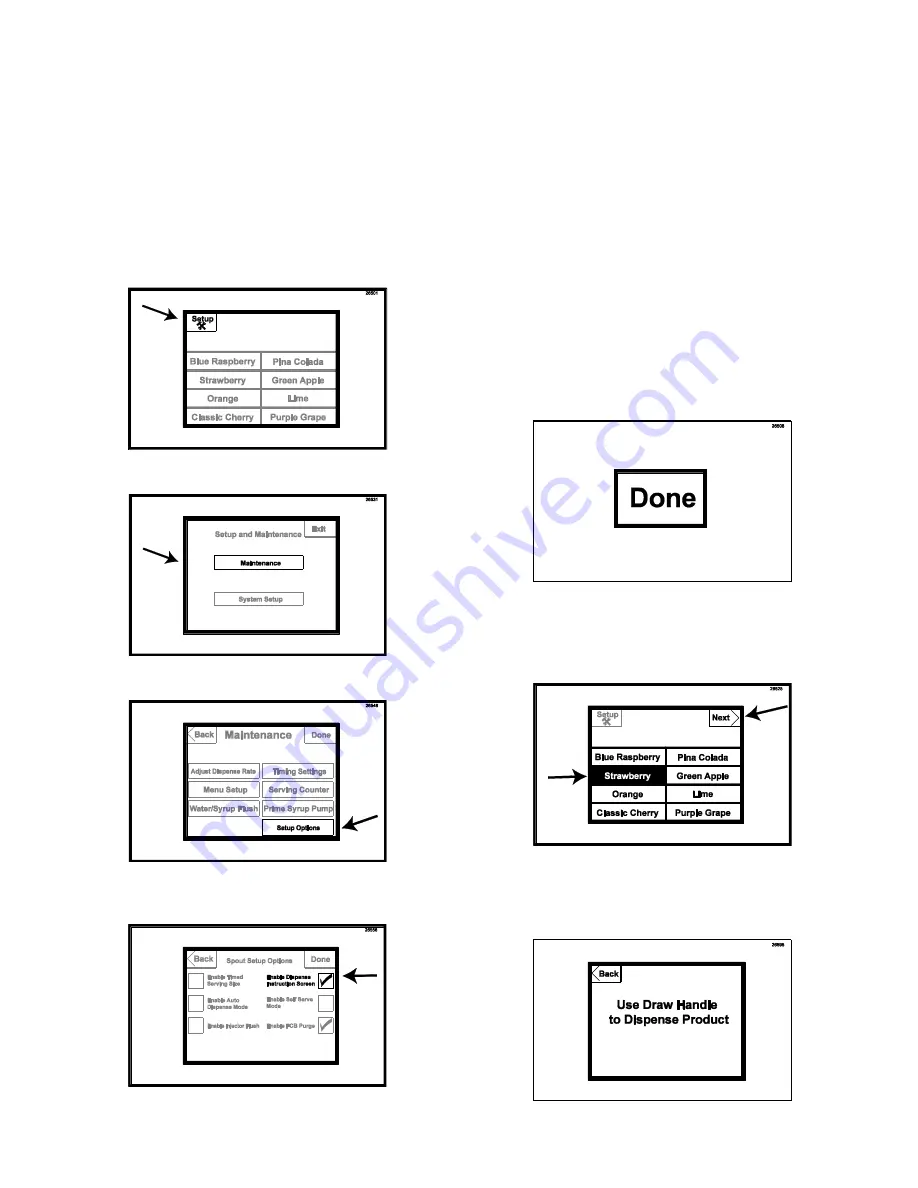

Enabling the Dispense Instruction Screen

In self-serve applications, you may find it helpful

to have step-by-step instructions on operating

the Touchscreen when drawing product. With

enabling the Dispense Instruction Screen, the

operator will go to the “next” screen after

making the flavor selections. That screen will

instruct the operator to draw a serving.

1. Press the SETUP key in the upper left

corner. Enter the password if required.

2. Press the MAINTENANCE key.

3. Press the SETUP OPTIONS key.

4. Press the box next to ENABLE DISPENSE

INSTRUCTION SCREEN to check the box.

NOTE:

TIMED SERVING SIZE AND SELF

SERVE MODE ARE OPTIONAL FEATURES

COMPATIBLE WITH THE DISPENSE

INSTRUCTION SCREEN. HOWEVER, THEY

ARE SHOWN UNSELECTED HERE IN THESE

ILLUSTRATIONS. ENABLING FCB PURGE IS

RECOMMENDED.

NOTE:

“ENABLE INJECTOR FLUSH” IS FOR

USE WITH NON-FCB SYSTEMS ONLY.

ENSURE THIS BOX IS

UNCHECKED.

NOTE:

“ENABLE AUTO DISPENSE MODE” IS

FOR USE WITH THE FCB AUTO DRAW

VALVE SYSTEM AND REQUIRES A SPECIAL

KIT FROM YOUR LOCAL DISTRIBUTOR.

5. Press the DONE key to return to the main

screen.

6. To test the instruction screen, select the

flavor(s) and press the NEXT key in the

upper right corner.

7. The next screen will show instructions on

drawing the product. After a few moments,

the screen will default to the main screen.

Summary of Contents for TS 80FCB

Page 4: ...3 PAGE INTENTIONALLY LEFT BLANK...

Page 7: ...6 General System Overview Figure 1...

Page 13: ...12 Syrup Pump and Related Parts Figure 4...

Page 15: ...14 Sanitizer Pump and Related Parts Figure 5...

Page 17: ...16 Electronic Parts and Connections Figure 6...