64

!

!

Planer-Thicknesser

A 941 / AD 941 / AD 951

Attention! Risk of material damage!

To obtain perfect working results it is necessary to strictly observe the manual guidelines and maintenance

instructions!

Attention! Risk of material damage!

Only use genuine Felder-Group carbide inserts due to their specific geometry. Due to safety reasons only use

genuine Felder-Group clamping screws for carbide inserts.

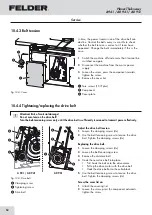

11.7.1 Safety instructions

• Only change the carbide inserts if the main switch of

the machine is on off.

• Only use genuine Felder-Group carbide inserts. Only

use genuine Felder-Group clamping screws. (see:

spare parts list)

• Only use the cutterblock with the appropriate safety

equipment. This applies particularly to the planer

guard.

• The tightening torque of the clamping screws has

to be in the specified torque range and should

neither be below nor exceed this range. It is strongly

recommended to use a torque wrench. Check the

correct setting of the torque wrench before each use.

(see: spare parts list)

• The use of a motorized or pneumatically powered

screwdriver to screw the inserts is not allowed!

• Check whether ALL screws are tightened correctly

before switching on the machine.

• The operation of the silent power cutterblock is only

allowed if ALL pockets are equipped with carbide

inserts.

• Check the carbide inserts and clamping screws for

damages with each change. If any damage occurs,

it is strictly forbidden to use the carbide inserts or

clamping screws.

• Check the threads of the pockets for damage and

ease of glide with each change. The machine may not

be switched on if the threads do not glide easily or the

required torque is not achieved.

• Ensure that the carbide inserts are aligned correctly

and are placed into the pocket at the correct angle

prior to tightening the clamping screw.

• Examine the pockets of the cutterblock for damages

when changing the carbide inserts.

• If there are any damages of the pockets recognisable,

the machine must not be switched on. Damaged

pockets may lead to the carbide inserts breaking!

• It is not authorised to use spanner-extensions to tighten

the carbide insert clamping screws. It is not authorised

to tighten the insert clamping screws using a hammer

for beating.

Note:

The silent power cutterblock is a high precision tool for woodworking.

This cutterblock was designed in conformity with the standard EN 847-1.

BG Test certified - Inspection n°: 139-063

US Pat. No. 7,708,038 and other patents pending

11.7 Cutterblock - Silent Power®

Faults

Summary of Contents for AD 941

Page 13: ...13 Planer Thicknesser A 941 AD 941 AD 951 Safety...

Page 67: ...67 Planer Thicknesser A 941 AD 941 AD 951 Faults...

Page 69: ...69 Planer Thicknesser A 941 AD 941 AD 951 Annex...

Page 70: ......

Page 71: ......