8

MACHINE RUNNING OPERATIONS

8.2

Threading preparation

8.2.1

Horn threading for Blake stitching

8.2.2

Horn thread stripper plug adjustment

8.2.3

Shuttle spool threading order

8.3

Position of article for stitching

9

MACHINE USE

9.1

Work cycle description

9.2

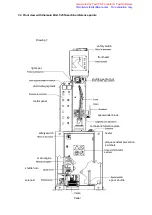

Machine electrical layout plan

9.3

Machine compressed air pneumatic layout.

10

REPLACEMENT OPERATIONS

10.1

Heater resistor replacement

10.2

Shuttle heater resistor replacement.

10.3

Needle replacement.

10.3.1 Needle size to be used according to thread size.

10.4

Loop opener replacement

10.5

Loop opener support replacement

10.6

Whirl replacement.

10.8

Needle support replacement

10.9

Flexible cord (for the horn) replacement

10.10 Flexible sheating (for the horn) replacement

11

ACCESSORIES

11.1

Heating equipment

11.1.1 Spool stripper plug adjustment

11.2

Shuttle spool preparation using the spool winder

12

MOUNTING OPANKA AND BLAKE HORNS FOR MACHINE

12.1

Replacement of Blake stitching horn with Opanka horn.

12.2

Mounting of BLAKE horn.

13

REPAIRS AND MAINTENANCE

13.1

Maintenance.

13.2

Normal periodic maintenance operations

13.3

Information concerning lubrification operations

13.4

Operations which must be carried out only by manufacturer’s qualified personnel

13.5

Possible problems that can arise

13.6

Spare parts and parts subject to wear and tear

13.7

Equipment supplied

14

DEMOLITION INSTRUCTIONS

15-1

SEWING MACHINE NOISE LEVEL

15-2

SEWING MACHINE VIBRATION LEVEL

16

PRINCIPAL WARNINGS

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com For evaluation only.