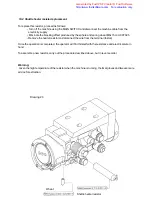

Daily oil lubrification

Monthly oil lubrification

13.3

Advice concerning lubrification.

The machine should be lubrified every day at the beginning of each work shift. Particular care should be

taken with all rotating and sliding parts .

The choice of oil is very important, since it must be neither too fluid nor too dense. The recommended

viscosity is : 30 - 40 ° SAE (ESSO NUTO 220 or equivalent brands)

At each bobbin change, oil the inside of the shuttle well before inserting the bobbin support.

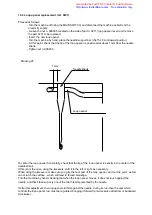

Lubrify the thread passageof the whirl regularly, putting a drop of oil, after having removed the whirl cover

plate.

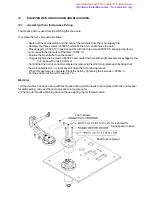

Once a day put a drop of oil in all the horn holes.

Warning:

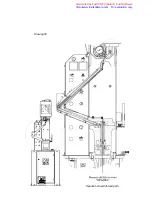

1) Before starting up the machine, lubrify all parts as described in the table shown below.

2) All the operations listed above must be carried out with the machine switched off and the machine

disconnected from the main supply line.

Lubrification Table

Monthly greasing

Drawing 31

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com For evaluation only.