6.

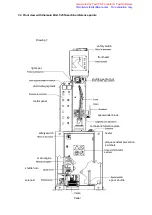

SETTING UP AND PREPARATION OF THE MACHINE READY FOR USE.

6.1 Accessory assembly.

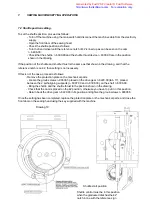

The machine is completely assembled in the manufacturing plant.

6.2 Preliminary control checks.

On reception of the machine, it is adviseable to:

- check that all the machine components have arrived at destination. (user’s plant).

- Run a series of preliminary control checks as described in the paragraph below.

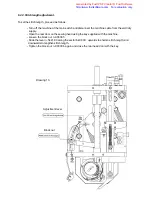

6.2.1. Check on any damage the machine may have suffered during transport.

In order to establish any damage the machine may have suffered during transport, control the condition of

the following parts:

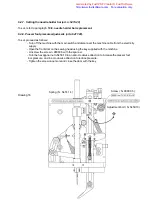

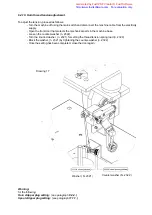

- flexible tubing and piping of the compressed air equipment,

- protection systems mounted on the machine,

- electrical wiring, electrical and pneumatic components.

- electric motors

- transmission V-belt

- horn

-all jutting out parts of the machine.

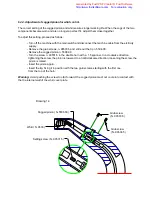

6.2.2. Machine cleaning procedure.

Clean the machine carefully removing all dust , dirt and foreign matter that may have deposited during

transport.

Eliminate all traces of anti-rust protection that has been sprayed on the machine against humidity.

Remove any grease that has been used to protect non-painted parts.

Warning:

For machine cleaning, wear protective gloves, and disconnect the electrical installation by removing the

machine cable from the electricity suuply.

To clean the machine, use products which are biodegradable and easy to buy.

After having removed all the grease protection on the mechanical parts, lubrify all parts generously with

the oil supplied with the machine (see paragraph

13. repairs and maintenance

)

.

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com For evaluation only.