12)

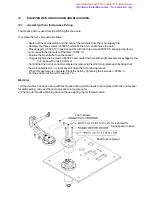

For best working conditions, the emulsion container should be filled with a solution of 80% water

and 20% emulsionable chemical oil. A can of this oil is supplied with the machine.

Before each production cycle, check the level of emulsion in the container, which should always

be almost full, and when necessary, top up the solution.

13)

The machine must always have THE MAIN SWITCH IN O POSITION and the machine cable

disconnected from the electricity supply when threading the machine. The compressed air

circuit must also be emptied.

14)

The upper part of the machine in the needle-shuttle area, is heated. Avoid touching this area

during maintenence operations; before any repairs or mainteneance, wait till the shuttle has

cooled down.

15)

Before beginning the production cycle, wait till the shuttle has reached the temperature set on

the thermostat TEMPERATURE SETTING RESISTOR on the electrical control panel.

16)

Never start up the machine before having placed the article to be sewn in position between the

presser foot and the horn tip.

17)

The operator must always avoid any maintenence intervention in the needle-shuttle area while

the machine is running. The machine must always be switched off :MAIN SWITCH IN O

POSITION and the machine cable disconnected from the electricity supply.

18)

Before starting up the machine, lubrify all moving parts.

19)

Sewing speed is controlled by the command pedal; the further it is pressed down, the faster the

speed.

20)

While the machine is running, it is absolutely forbidden to remove the protection systems

provided by the manufacturer for the operator’s safety.

21)

Before carrying out any kind of maintenance operations

remember to close the compressed air

draft tap located near the filter-reducer block mounted on the machine, and to empty the

pneumatic circuit of all compressed air.

22)

All operations described in this manual must be carried out only after:

- switching off the machine. MAIN SWITCH IN O POSITION.

- disconnected the machine cable from the elctricity supply

- closed the compressed air draft tap located near the filter-reducer group mounted on the

machine, and emptied the pneumatic circuit of all compressed air.

All rights reserved.

The reproduction of this manual is prohibited, even partially, and in any form whatsoever (printed,

photocopied, microfilmed, or other methods) as well as by computer processing, reproduction or

diffusion using electronic means.

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com For evaluation only.