25

PROBABLE CAUSES

CORRECTION

PROBABLE CAUSES

CORRECTION

Circuit board not working. (62)

Change the circuit board. (62)

PROBABLE CAUSES

CORRECTION

Water valve (63) does not close (yellow LED on).

Change the water valve. (63)

Water does not touch the water level

sensor (55) (yellow LED on).

Regulate the mobile water level sensor. (55)

Water level sensor (55) has incrustations (yellow LED on).

Clean the water level sensor. (55)

Circuit board not working. (62)

Change the circuit board. (62)

Loss of refrigerant gas.

Check, correct and recharge with correct load.

Dirty condenser. (25)

Clean the condenser. (25)

Blocked air circulation.

Move the machine to an appropriate location.

Low water level in the plastic trough. (35)

Adjust the water level sensor. (55)

Gas solenoid valve allowing hot gas to pass

through, even when it is switched off. (28)

Change the gas solenoid valve. (28)

Tank thermostat lacking adjustments. (61)

Replace or adjust the tank thermostat. (61)

Compressor with compression loss. (23)

Change the compressor (23)

(see compressor/gas load change) (p.33).

Fan not working (24) (only for EGC-150A model).

Change the fan. (24)

2.5 - LOW ICE PRODUCTION

2.4 - CONTINUOUS ENTRANCE OF WATER IN THE TROUGH

2.3 - WATER TROUGH GOES UP AND DOWN CONTINUOUSLY

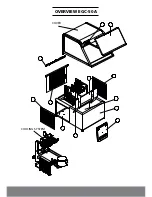

Summary of Contents for EGC 100 A / 150 A

Page 12: ...OVERVIEW EGC 50A COVER COOLING SYSTEM...

Page 14: ...13 I OVERVIEW EGC 150MA I...

Page 15: ...14 COOLING SYSTEM EGC 50A EGC 75A EGC 100A AND EGC 150A I COOLING SYSTEM EGC 150MA I...

Page 16: ...ELECTRICAL ELECTRONIC PART...

Page 17: ...TROUGH DISPLACEMENT SYSTEM DISPLACEMENT ARM ASSEMBLY TROUGH...

Page 36: ...35...