23

6 -SYMPTOM: TROUGH (35) RISES, BUT

DOES NOT ACHIEVE THE HIGHEST POINT

Probable causes:

• Damage to the displacement system

(reversible defect)

.

• Gear motor (60) not working

(irreversible defect)

.

• Ice cubes inside the plastic trough (35)

(reversible defect)

.

• Upper Reed Switch (54) not working or lacks adjustment

(irreversible defect)

.

• Displacement system spring damaged

(irreversible defect)

.

• Tank thermostat (61) not working/lacks adjustment

(irreversible defect)

.

The plastic trough (35) has up to 10 seconds to reach its highest position. When this does not

occur, the circuit board (62) executes actions to try to remove ice cubes from inside the plastic

trough (35). The sequence of operations performed by the circuit board (62) consists of "taking" the

plastic trough (35) to the highest point, by "compressing" the ice cubes against the thimbles of the

evaporator (20). After that, it will switch on the gas solenoid valve (28) for 1 minute, causing the

thimbles to "perforate" the ice cubes. Then it switches off the gas solenoid valve (28) for 2 minutes

and allows the cooling system to "freeze" the ice cubes on the evaporator thimbles (20). After this

operation, the plastic trough (35) descends to the lowest position and starts a by-pass cycle to

allow the ice cubes which are attached to the evaporator thimbles to detach themselves and fall

into the ice tank. (6)

The actions performed above will be repeated 5 times, if necessary. After the attempts, if the plastic

trough (35) does not reach the highest point, the circuit board (62) positions the plastic trough

(35) at the lowest point, switches on the red LED light and waits for 10 minutes. After 10 minutes,

it switches off the red LED light and turns on the solenoid gas valve (28) for 45 seconds, cleaning

the evaporator (20) and preventing the accumulation of ice crystals in it, and starts another

attempt at normalizing the process.

7 - SYMPTOM: THROUGHOUT THE WATER INLET, THE

PLASTIC TROUGH (35) DOES NOT STAY AT THE HIGHEST POINT

Probable causes:

• Right spring (31) damaged

(irreversible defect)

.

• Plastic trough (35) lowered manually

(reversible defect)

.

In the EGC-100A, 150A-EGC and EGC-150MA automatic ice machines, there is a second spring set

(72), with the intention of supporting the plastic trough (35). When the spring set (72) breaks, the

weight of the water that has entered the plastic trough (35) moves it away from the highest

position, causing the opening of the upper reed-switch (54). This fact signals an anomaly to the

circuit board (62).

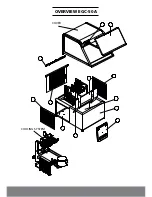

Summary of Contents for EGC 100 A / 150 A

Page 12: ...OVERVIEW EGC 50A COVER COOLING SYSTEM...

Page 14: ...13 I OVERVIEW EGC 150MA I...

Page 15: ...14 COOLING SYSTEM EGC 50A EGC 75A EGC 100A AND EGC 150A I COOLING SYSTEM EGC 150MA I...

Page 16: ...ELECTRICAL ELECTRONIC PART...

Page 17: ...TROUGH DISPLACEMENT SYSTEM DISPLACEMENT ARM ASSEMBLY TROUGH...

Page 36: ...35...