en

3. DEFINITION OF PICTOGRAMS

2.4 CLOTHING

The procurement of such personal pro-

tective equipment is the sole responsibil-

ity of the customer or employer.

During machine use and maintenance

operations:

The operator

MUST

always wear suitable

safety shoes, gloves, and hearing protec-

tion devices and wear long, resistant trou-

sers and safety goggles.

Do not wear loose-fitting clothing, jewelry,

ties, scarves, dangling drawstrings that

could get caught by the equipment . Tie up

your hair.

During unpacking and assembly:

The operator

MUST

always wear resistant

safety shoes, gloves, and clothing.

DANGER!

Keep all labels clean and in good condi-

tion, replace them if damaged.

INFORMATION!

2.2

2.2

2.1

2.1

4. TECHNICAL FEATURES

Model

MZP11

MZP12

GROSS and

NET weight

CE declaration label on

the last page

Rated power

Sound power

Acoustic

pressure

Vibrations

Tyres

13x5.00-6

Rotary cutters

diameter

320 mm

Rotary cutters

rotation

275/min

Forward speed

1^

1,1 km/h

Forward speed

2^

-

2,1 km/h

Reverse speed

in 1^

0,96 km/h

Reverse speed

in 2^

-

1,8 km/h

Concerning the engine technical data, please

see the enclosed instructions manual

2 or more people are required to handle

packaging, using the handles on the card-

board box. The GROSS weight is indicated

in the “TECHNICAL FEATURES” chapter.

CAUTION!

Do not overturn or roll the machine. Pos-

sible damage to bonnets and mechanical

parts.

INFORMATION!

If more than one machine or interchange-

able equipment is supplied on pallets,

unload without dropping them on the

ground. Use a forklift if necessary.

5. HANDLING AND PACKAGING

6. UNPACKING/ASSEMBLY

Unpacking

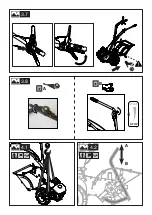

Handlebar support assembly:

secure the handlebar support (B) to the

frame (A), using screws (g) with washers (h)

in the two holes. Secure the knobs (m) with

washers (h), screws (i) and nuts (l) in the slot.

1.3

1.3

Rotavator assembly:

Insert

the widening tines (C) at the ends of the

other rotavators and secure them with the

screws (n) and nuts (o).

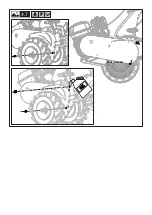

Rotavator cowling assem-

bly:

Unscrew the 6 screws from the seats

on the frame, then position the cowling

(D), taking care to match its slots with the

screw seats, and tighten the 6 screws.

1.5

1.5

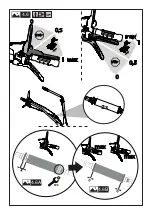

Rotavator cowling bracket

assembly:

Insert the hooks of the bracket

(E), holding this rotated upwards, into the

relevant slots on the Rotavator cowling.

CAUTION: The bracket must be positioned

with the hooks facing the same way as

in the enlargement shown, or rather the

hooks must enter from above into slit “B”

and exit from “A”.

Throttle assembly:

Depending

on the throttle supplied (A, B shown):

-Throttle A: hook terminals “x “ and “y”

of the throttle cables.

-Throttle B: unscrew the screw and nut

from the throttle, then screw back on the

handlebar.

The motor is supplied without lubricating

oil. For information on the type of oil and

quantities to be used, refer to the motor

manual contained in the accessory bag

[F].

1.1

1.1

7. USE

Do not start the engine until all assembly

stages have been completed.

Add lubricating oil to the motor before

first start-up. For information on the type

of oil and quantities to be used, refer to

the motor manual contained in the ac-

cessory bag [F].

1.1

1.1

Before starting the machine, check the

oil level inside the motor, as indicated in

1.1

1.1

1.2

1.2

*

1.4

1.4

*

1.6

1.6

CAUTION!

CAUTION!

CAUTION!

CAUTION!

Summary of Contents for MZP 11

Page 3: ...F A 1 1 1 1 g x2 E C i x1 h x4 l x1 m x2 D B o x2 n x2 x2...

Page 4: ...B 1 3 1 3 1 2 1 2 A g l g h h i h h m m o o n n C C A...

Page 5: ...1 4 1 4 D D...

Page 6: ...1 5 1 5 E E E A B...

Page 7: ...8 B 1 6 1 6 1 7 1 7 1 2 3 5 6 7 8 8 9 4 x B x y y A A x x y y x y x A x x y y A B...

Page 10: ...3 1 3 1 10 m 3 3 3 3 OIL FUEL OIL 4 7 4 7 3 2 3 2 3 1 2...

Page 11: ...3 6 3 6 3 5 3 5 3 4 3 4 START STOP A B...

Page 12: ...3 7 3 7 3 8 3 8 START STOP 4 2 4 2 4 1 4 1 A B A B...

Page 13: ...4 4 4 4 35 35 4 3 4 3 4 5 4 5...

Page 14: ...STOP 1 max 0 5 0 STOP 0 0 5 1 max M10 X 0 0 max max max max 2x 4 6 4 6 4 6A 4 6A 4 6B 4 6B...

Page 15: ...4 7 4 7 1 O IL 2 Max oil level 1 1 2...

Page 58: ...el 1 1 1 1 2 CE 1 3 2 1 2 1 1 4 CE CE 2 1 2 1 1 2 3 4 5 6 7 8 2 1 16 2 3 4 5 6 80 7 8 9 10 1...

Page 63: ...el SAE 80 10 6 21 PSI 1 5 bar PSI 11 20 11 10 6 10 4 60 10 5 12 13 7 2 START 1 7 3 10 4 10 4...

Page 64: ...el 14 14 1 2002 95 CE 2002 96 CE 2003 108 CE 14 2 81 08...