82

Maintenance

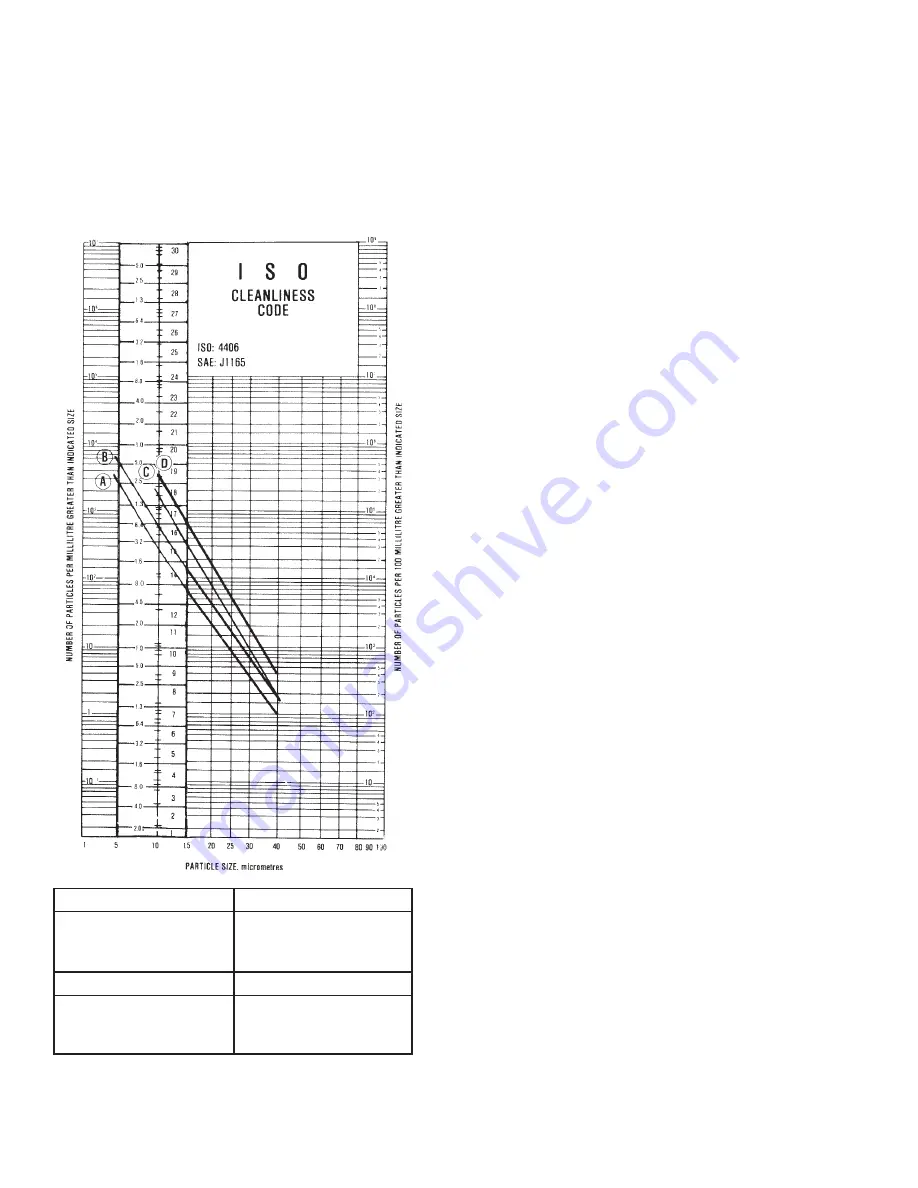

Contamination Levels

Clean fluid implies the absence of impurities such

as solid particles, water and air. Contamination

control includes proper design, installation, and

maintenance of hydraulic components.

The reservoir is designed to limit entry of

contamination during servicing and operation. A

sealed reservoir with a low pressure relief valve

reduces the introduction of contaminants while

maintaining inlet and case drain pressures below

the maximum recommended.

The purpose of the filter in a system is to clean

the oil at initial start up and to maintain acceptable

levels of particle contaminants as they are ingested

or generated during operation of the system.

Filtration is a matter of controlling the particle

sizes and their respective quantities to appropriate

levels so as to avoid degradation of the system

components and thereby assure the desired life.

Fluid contaminant profile requirements for Etnyre

hydraulic units have been determined empirically

based on measuring fluid quality in successful

application, and in laboratory tests designed to

evaluate hydraulic unit contaminant sensitivity.

General contaminant levels have been developed

based on this experience and are shown in Figure

32.

Acceptable contamination levels at machine start

up for the system loop should be equal to or better

than Curve D. The machine may be exercised to

500 psi but should not be worked (pressure over

500 psi) until the oil cleanliness meets or exceeds

Curve C.

The machine should clean up during a relatively

short period of normal operation to meet the oil

cleanliness level of Curve A or Curve B. A system

that meets Curve A will provide the user with a

longer trouble-free operating life than one that

meets Curve B. The Curve A cleanliness level

should be met in systems exceeding the continuous

pressure limit for 1000 hours/years machine use.

Some control valves may require better

contamination limits than specified in

Figure 98.

Controls with small area screens or low force level

values may be susceptible to malfunction from

contamination.

The contamination sensitivity of components

generally increases with higher pressure,

temperature or speed. A better fluid contaminant

profile may be required for systems which operate

near the extremes of their ratings. Short life or

infrequent operation requirements may increase

allowable contaminants.

Figure 95. Fluid Cleanliness Chart

Curve A

Curve C

Desired limit for longer

Limit at machine ship

life (3500 PSI continuous

and new fluid added to

system pressure)

transmission

Curve B

Curve D

Continuous operating

Limit at machine start up

limit (2000 PSI continuous

pressure) system

The selection of a filter depends on a number of

factors including the contaminant ingression rate,