EPSON Stylus Pro 7500

Revision A

Adjustment

Adjustment Steps

191

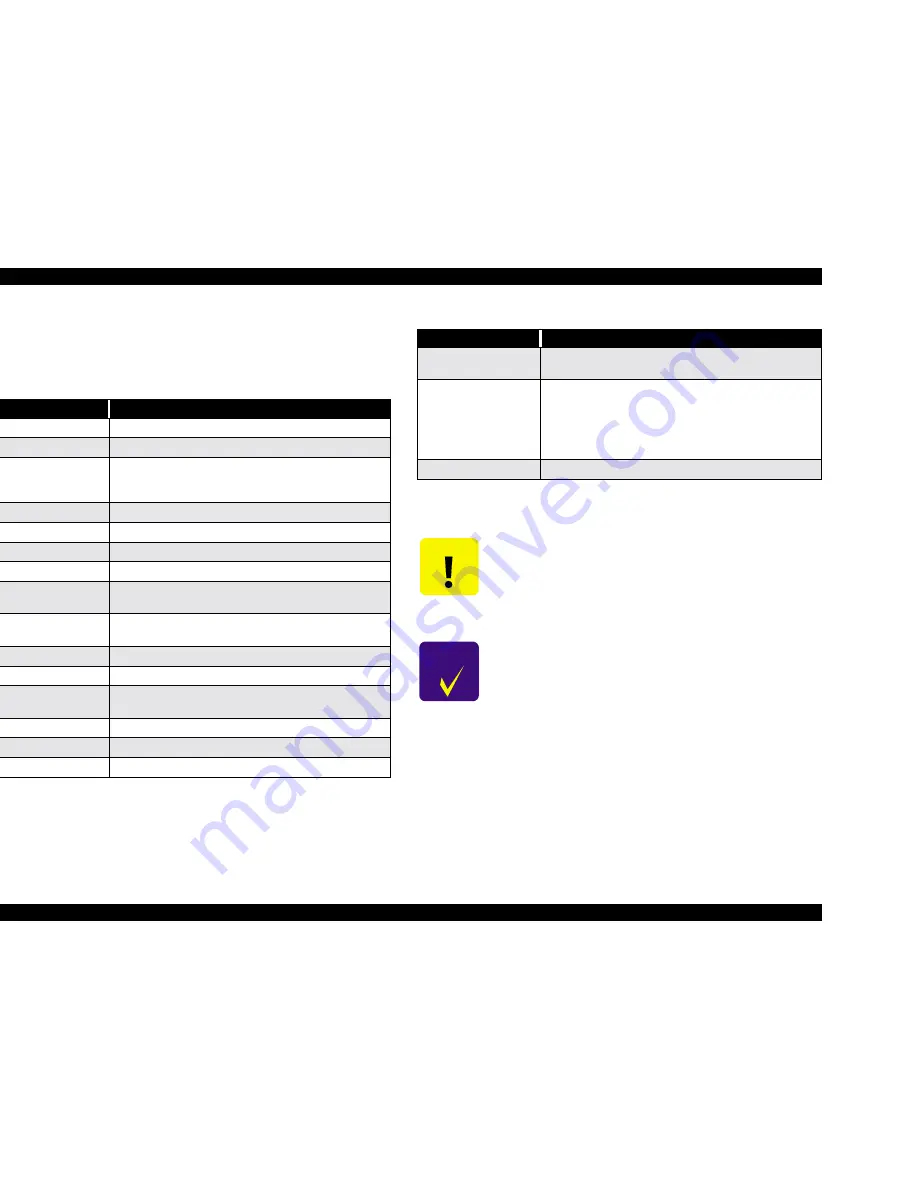

5.2.3.4 Adjustment Menu

The Adjust menu allows you to make certain adjustments to the printer mechanism and

controls, for example head angle adjustment, print position adjustment, paper feeding

correction, and firmware-control setting.

*1 These should definitely be executed after the new C299MAIN board has

been installed.

Table 5-9. Adjustment Menu Items

Adjustment Item

Description

Capping Position

Sets the Capping position (automatic Adjustment)

Paper Skew Check

Verifies the degree of skew (slant) allowed during printing

Write D/A Value

Writes the direct/alternate data to the Flash ROM; *1 compensates

for differences in individual Main Boards - like head ID for the

Main Board

Head Rank Input

Sets the printhead ID

Head Nozzle Check

Prints the check pattern to make sure the nozzles are not clogged

B Head Angle

Adjusts the angle of the B Head (mechanism adj.)

C Head Angle

Adjusts the angle of the C Head (mechanism adj.)

BC Head Height

Verifies the B/C Head nozzles are at the same height (mechanism

adj.)

Bi-D Print Position

Verifies the printed lines match up when performing bi-directional

printing.

Head Gap

Adjusts the B/C Head Gap as well as sets the left margin

R Flush Point

Adjusts the flush position on the HP side

L Flush Point

Do not use, there is no left flush point and this function will

generate a fatal error

Feed Correction

Checks paper feeding (w/ruler)

Top & Bottom

Checks the top and bottom margins (w/ruler)

Rear Paper Sensor Position Sets the detection position of the rear paper-edge sensor

Test Pattern Print

Checks print quality (prints setting information, check pattern and

so on)

Clean Head

Initiates cleaning/flushing of the heads and ink path

1) Ink drain

2) Fill with transportation fluid (1 time = 15ml)

3) Drain transportation fluid

4) Reset the ink charge flag

Counter Clear

Resets all counters in Table 5-13 on page 210

C A U T I O N

n

Use the transport liquid cartridges (x 6) for “Head Cleaning.” It

is also possible to substitute “Transport Liquid Initial Filling -

Transport Mode.”

n

“Counter Clear” should only be carried out during replacement

of periodic replacement parts produced in the “Maintenance Kit,

Stylus Pro 7500,” which includes the waste ink pads.

C H E C K

P O I N T

n

When replacing the C299MAIN board, be sure to carry out

writing of the D/A correction values. This parameter is measured

during manufacturing of the circuit board, and is written to the

USB EEPROM on the board. This parameter exists in a Flash

ROM area that cannot be copied during parameter backup with

a PC card, so it should be carried out from the USB EEPROM on

the new board.

Table 5-9. Adjustment Menu Items (continued)

Adjustment Item

Description

Summary of Contents for Stylus Pro 7500

Page 1: ...EPSONStylusPRO7500 Color Large Format Inkjet Printer SEIJ00005 SERVICE MANUAL ...

Page 6: ...Revision Status Revision Issued Date Description Rev A August 31 2000 First Release ...

Page 10: ...C H A P T E R PRODUCTDESCRIPTION ...

Page 57: ...C H A P T E R OPERATINGPRINCIPLES ...

Page 75: ...C H A P T E R TROUBLESHOOTING ...

Page 95: ...C H A P T E R DISASSEMBLY ASSEMBLY ...

Page 169: ...C H A P T E R 0 ADJUSTMENT ...

Page 192: ...PSON Stylus Pro 7500 Revision A djustment Adjustment Steps 192 Figure 5 13 Adjustment Menu ...

Page 235: ...C H A P T E R MAINTENANCE ...

Page 241: ...C H A P T E R APPENDIX ...

Page 258: ...PSON Stylus Pro 7500 Revision A ppendix Exploded View Diagram 258 Figure 7 2 Frame Assembly ...

Page 260: ...PSON Stylus Pro 7500 Revision A ppendix Exploded View Diagram 260 Figure 7 4 Head Assembly ...

Page 262: ...PSON Stylus Pro 7500 Revision A ppendix Exploded View Diagram 262 Figure 7 6 Frame Accessory ...

Page 265: ...PSON Stylus Pro 7500 Revision A ppendix Exploded View Diagram 265 Figure 7 9 Cable Guide ...

Page 267: ...PSON Stylus Pro 7500 Revision A ppendix Exploded View Diagram 267 Figure 7 11 Cover Assembly ...

Page 272: ......

Page 273: ......

Page 274: ......