6.1.2 Service Maintenance

This section describes the periodic service maintenance and cleaning required.

6.1.2.1 Periodic Service Maintenance

The following units require periodic service maintenance because they are subject to functional

deterioration as the total number of printed pages increases, resulting in bad print quality.

Table 6-1. Periodic Service Maintenance

Unit

Service Interval

Imaging Cartridge

APPROX. 4,800 to 6,000 pages

Paper Take-Up Roller

APPROX. 100,000 pages

Image Transfer Roller

APPROX. 50,000 to 100,000 pages

Fusing Unit

APPROX. 50,000 to 100,000 pages

The service interval listed above is only a reference value. You do not need to perform service

maintenance exactly at this time.

6.1.2.2 Cleaning

Some parts of this printer require regular cleaning. For example, whenever the paper jams during

paper loading or when print quality problem happen.

Clean each part using the specified method and tools. (Refer to Chapter 3 for disassembly

procedures.)

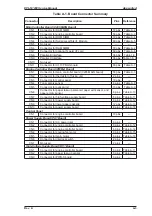

Table 6-2. Cleaning Parts and Procedures

Parts Name

Cleaning Procedure

Image Transfer Roller

Wipe the surface with a dry soft cloth.

Optical Lens

Paper Take-Up Roller

Upper Fusing Roller (in Fusing Unit)

Dip a soft cloth in silicon oil and wipe the dust off.

Lower Fusing Roller (in Fusing Unit)

Thermistor (in Fusing Unit)

Dip a soft cloth in denatured alcohol and wipe the

dust off.

Thermostat (in Fusing Unit)

Paper Separator and Rollers (in Fusing Unit)

EPL-N1200 Service Manual

Maintenance

Rev. A

6-3

Summary of Contents for EPL-N1200

Page 1: ...EPSON TERMINAL PRINTER EPL N1200 SERVICE MANUAL EPSON 4006838 ...

Page 8: ...REVISION SHEET I Revision I Issue Date Revision Page Rev A December 9 1996 1st issue vii ...

Page 111: ...Chapter 4 Adjustment No adjustment is required in this product ...

Page 127: ...6 ii Rev A ...

Page 133: ...Figure A 2 Engine Section Cable Connection Appendix A EPL N1200 Service Manual A 2 Rev A ...