APPENDIX C: SYSTEM CALIBRATION

Camera Calibration

Note:

Camera calibration on the Fusion

Pro is only necessary if recommended

by Epilog’s Technical Support.

Note:

Before beginning, reboot your

machine if you have recently run any

jobs.

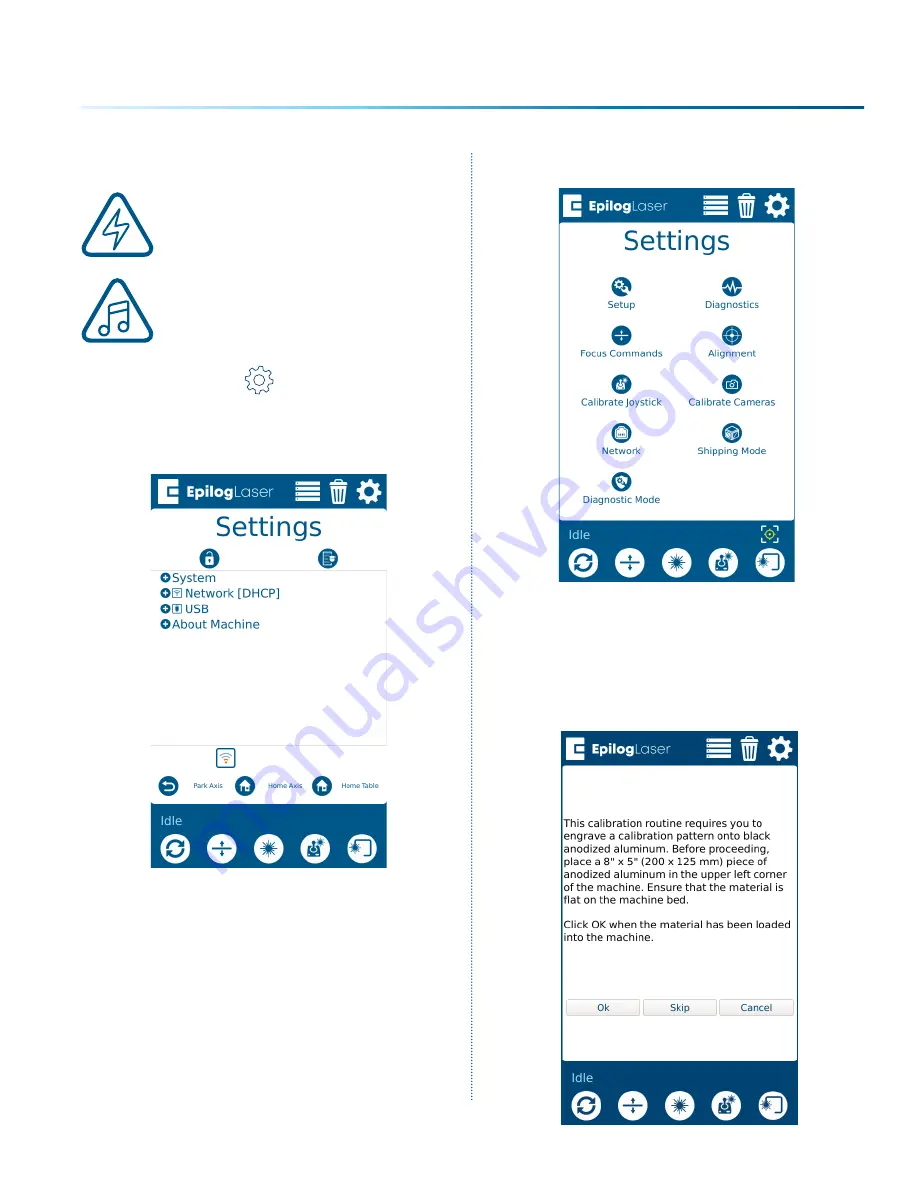

1. Click the

Settings

button to enter the

Settings menu.

2. Long Press the

“Settings”

text for 5 seconds

to enter the Advanced Settings Menu.

3. Click on

“Calibrate Cameras”

to enter the

Camera Calibration menu.

4. While the machine is Idle, follow the prompt,

and begin the calibration routine by selecting

“Ok”

. The calibration pattern mentioned in

the prompt will be used by the single camera

at the laser head. Use an 8” x 5” (203 x 127 mm)

or larger piece of anodized aluminum. (You

can also optionally skip this step by clicking

Skip.)

- 217 -

Summary of Contents for Fusion Pro 32

Page 2: ......

Page 6: ......

Page 14: ...Fusion Pro 48 8 SECTION 1 SAFETY ...

Page 15: ... 9 SECTION 1 SAFETY ...

Page 18: ......

Page 28: ......

Page 60: ......

Page 98: ......

Page 108: ......

Page 132: ......

Page 162: ......

Page 184: ......

Page 202: ......

Page 214: ......

Page 216: ......

Page 242: ......