54

Elcom, spoločnosť s ručením obmedzeným, Prešov

Elcom, spoločnosť s ručením obmedzeným, Prešov

55

Uniq 150

Service manual

Service

manual

Uniq 150

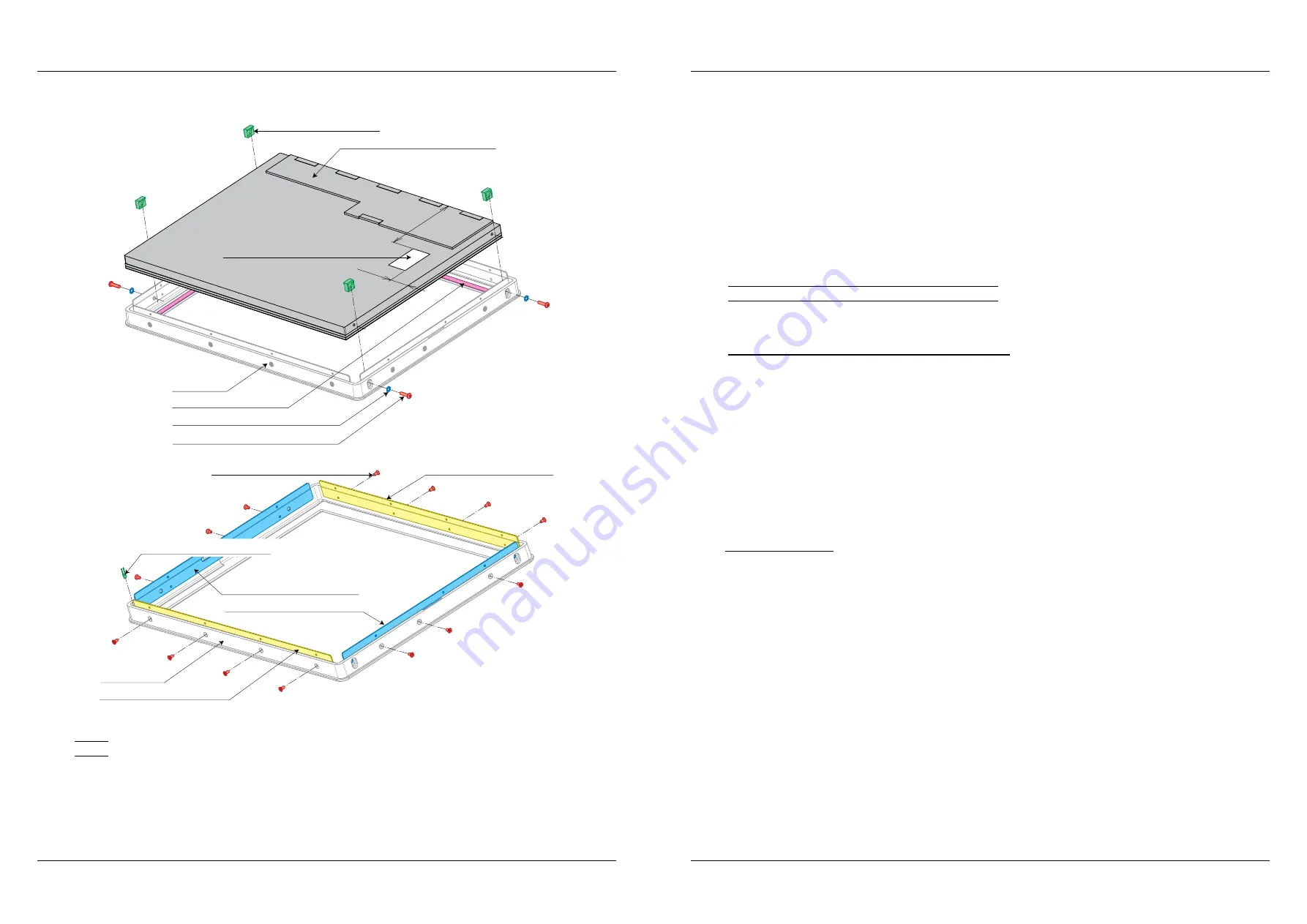

Figure 2.25.3. – Replacement of display with capacitive touch panel

33,5

96

Serrated lock washer M3 DIN6798

Screw M3 × 12 mm BN13255

LCD clip

Capacitive panel 15“ vandal proof

Tape TESA 4957 6 mm

Front cover

Insulation foil 25 × 12,5 × 0,25 mm

LED KM-2520VGC-A03 green

Screw M2,5 × 5 mm DIN965

Metal joining strip PP5000 TL

Front cover

Metal joining strip L PP5000 TL

Metal joining strip P PP5000 TL

Metal joining strip PP5000 TL

Note:

It is possible to use prepared maintanace sets of front panels Maintanace sets without display are primary used

for models with AUO display version, but they can by used for Turbo touch too.

In case of AUO verzion, there is neccesary to take out original display.

P280180000 Touchpanel resistive black frame-black multi TL without display

P2801800000 Touchpanel resistive white frame-white single TL without display

P2801800001 Touchpanel resistive gray frame-white single TL without display

P2801800002 Touchpanel resistive gray frame-black multi TL without display

Next sets are installed by display:

P2801800005 Touchpanel resistive black frame-black multi TL with display

P2801800006 Touchpanel resistive white frame-white single TL with display

P2801800007 Touchpanel resistive gray frame-white single TL with display

P2801800008 Touchpanel resistive gray frame-black multi TL with display

2.26. LED replacement and interconnection

2.26.1. Replacement and interconnection of lightguide

The lightguide consists only execution with AUO kit. The lightguide will be most likely demaged if the

lightguide is necessary to remove or is needed to replace some of the LED diodes.

It is necessary prepare before replacement:

–

tools for breaking removal of the lightguide and tools to clean lightguide remains the front cover

–

tin and soldering

–

Silicone OTTOSEAL black vandal – M990144

–

Power glue Loctite 401 – M250007

–

Tubing 2,4 mm – M010004

Process of replacement:

The lightguide is stick to the front cover with power glue and gaps between lightguide and cover are

filled with silicone because of IP protection.

1.

Truss and nick the lightguide with thin flat tool (shaver or screwdriver).

2.

Clean the cover of the remains of lightguide, silicone and glue.

3.

Glue diodes with cable on a new lightguide. There is a resistor 220R 0,6W on each of LED diode anode

to reduce the voltage.

4.

Put lightguide into front cover and spread a little of power glue on three protruding tabs from inner cover

side to fix lightguide in front cover.

5.

Fill gaps between lightguide and front cover edge from outher side with silicone.

Note: Installation of lightguide must be executed precisely according to figure. Note all the gaps are filled with

silicone, otherwise IP54 protection class cannot be guaranteed!

Summary of Contents for Uniq 150

Page 1: ...Uniq 150 Uniq 150 Service manual version 1 4 Elcom spolo nos s ru en m obmedzen m Pre ov...

Page 5: ...Elcom spolo nos s ru en m obmedzen m Pre ov 5 Service manual Uniq 150 1 General specification...

Page 7: ...Elcom spolo nos s ru en m obmedzen m Pre ov 7 Service manual Uniq 150 2 Structural part...