EBS-6100

Printer User's Manual

Paragraph 5 - Examples of How to Operate the Printer

EBS

Ink-Jet Systems

®

96

20070529#20.5

5.

Examples of How to Operate the Printer

NOTE:

It has been assumed that the user has become familiar with the manual or has at least read

chapter

4 Operating the Printer

.

5.1. How to Print the First Sample Text File

This chapter contains a description of how to prepare the

EBS-6100

printer for

operation and how to print a simple text file. The example covers instructions on how to install

a new machine, switch it on, set major parameters and print a text file that has been input via

a terminal.

1)

If the printer is installed by the Manufacturer or authorized service staff, this section can

be omitted. Otherwise

the procedure below needs to be followed to install the

printer

:

Read section

2.1

Safety Requirements

.

Follow the instructions given in section

2.3

Installing the Printer

.

2) Place the print head in a holder in such a position that nobody or nothing can be

splashed with ink accidentally

. Therefore position the head horizontally at first and

place a shallow ink dish under it.

NOTE:

If a sound alarm occurs while the below specified procedure is followed, try to find

the reason for the alarm by studying the indications.

3) Switch the printer on by pressing the green

ON

key on the external panel.

4) Check whether the partial vacuum pump operates -

the usual whirr is heard when the

lamp V91 on the internal panel comes on. The pump turns on and off in cycles.

5) About 3 minutes after switching the printer on check for proper phasing by viewing

the head status

. See section

4.3

Print Head Status

.

NOTES:

•

The head status referred to may vary frequently over the first 3 minutes after the unit

has been switched on, because ink of varying density flows into the head from supply

pipes.

•

If the phasing fails to reach right results within about 3 minutes of the switching on,

a phasing error occurs.

6) Use the terminal keypad to create a text file to be printed.

In the main MENU select the

TEXT SERVICE

item and then the

CREATE NEW TEXT

item.

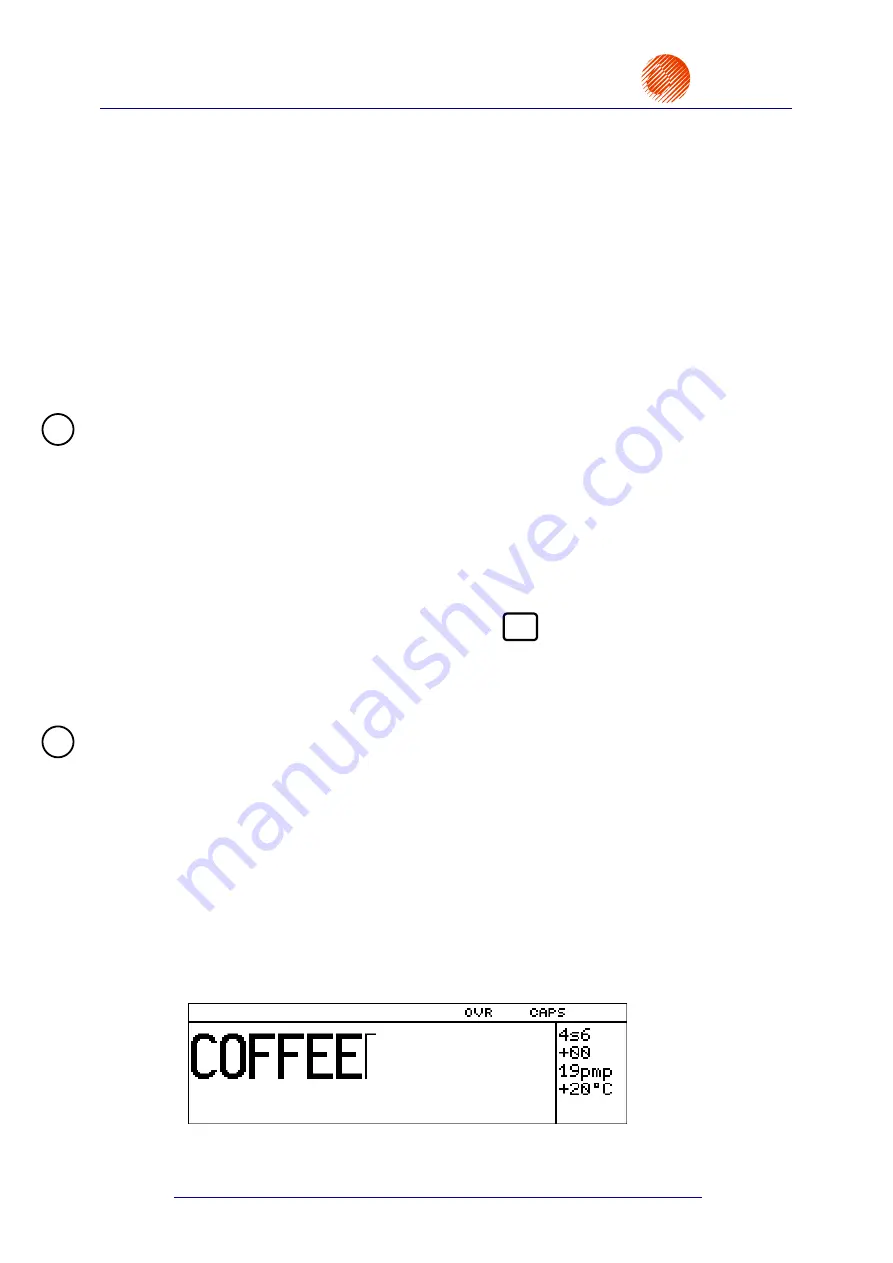

After the text file name, e.g. TXT1, has been specified, the text processor starts running.

Now you can use the keypad to input what is to be printed. A description of the processor

control keys is given in section

4.4.1.1

General Information on Text Files

, paragraph

WORD PROCESSOR - A Description of Control Keys

.

!

!

Summary of Contents for EBS-6100

Page 1: ...EBS Ink Jet Systems EBS 6100 USER S MANUAL...

Page 2: ......