32

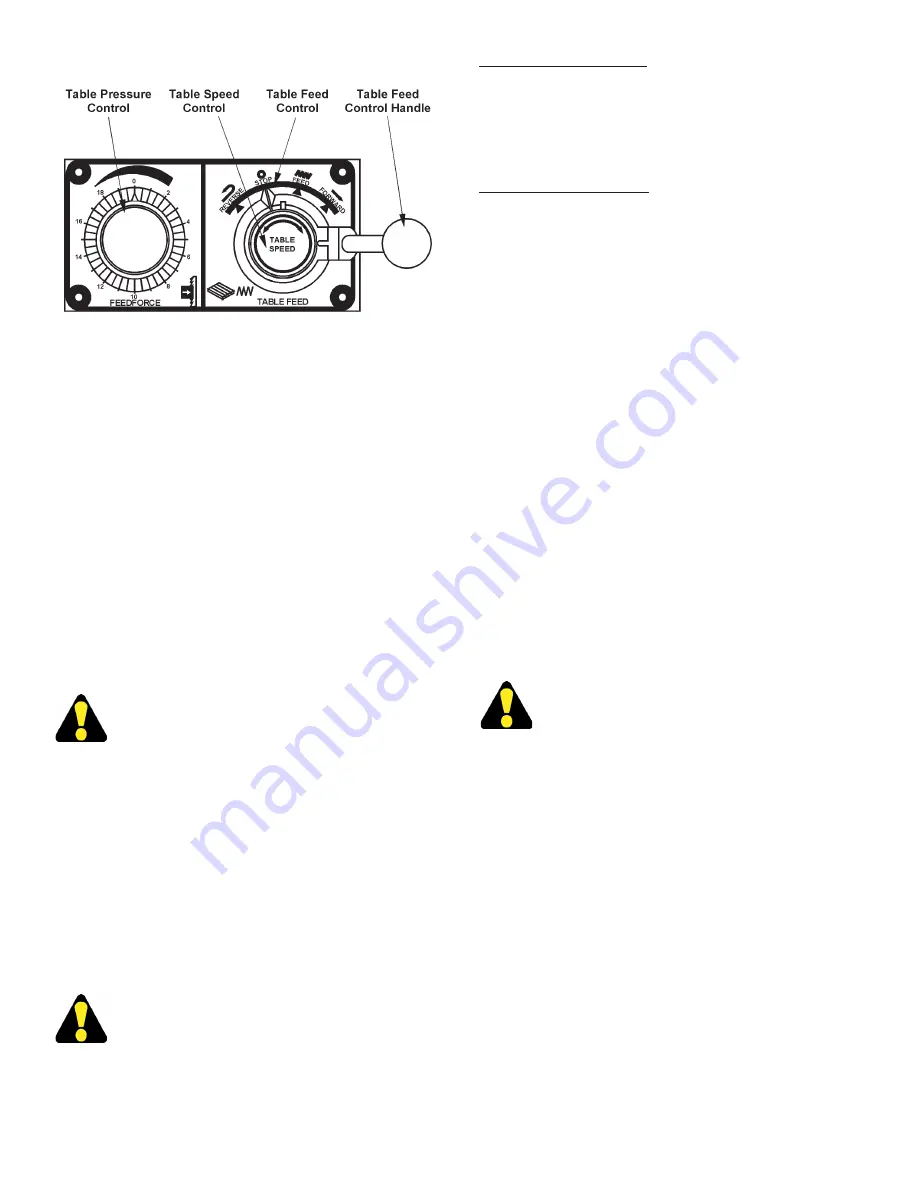

Table Controls.

•

Table Speed.

This dial located in the center of the

Table Feed

control regulates the table speed. Turn

the dial

clockwise

to “increase” table feed speed,

counterclockwise

to “decrease” it. This operates

in the “feed” position only.

GLIDE TABLE

1.

This non-tilting worktable option has a 25.39 by

32.63 inch (644.9 by 828.8 mm) worktable and table

travel of 18.00 inches (457.2 mm). Load capacity

is 250 pounds (113.4 kg).

2.

The workpiece is securely clamped to the table.

The operator then holds the handle in front of the

table and manually pushes the table with the work-

piece through the saw band. The handle also acts

as a workstop if desired.

DO NOT force workpiece through the saw

band.

3.

A thumbscrew located in the lower right under the

worktable locks the worktable in place to allow load-

ing and unloading of stock. Loosen the thumbscrew

completely for the worktable to move freely.

4.

The handle must be removed for saw band

changing.

OPTIONAL SAW GUIDES

1.

The following optional saw guides may be used to

help increase productivity and economy.

Information and availability of all DoALL saw

bands and guides can be obtained from a

DoALL sales representative.

Insert Type Saw Guides

1.

Insert type saw guides are designed for lower range

band speeds. See the

“Operation”

section of this

manual for use and adjustments for these saw

guides.

Roller Type Saw Guides

1.

Roller type saw guides are designed for high range

band speeds. See the

“Operation”

section of this

manual for use and adjustments for these saw

guides.

EXTRA WORK HEIGHT

1.

The factory installed extra work height allows

maximum cutting capacity up to 42 inches

(1066.8 mm). Machines with this option have

an auxiliary post support, plus a slightly different

frame weldment, post guarding, and hydraulic

post cylinder from those shown elsewhere in this

manual.

HYDRAULIC BAND TENSION

1.

A factory installed cylinder mounted next to the upper

bandwheel spindle applies the correct tension to the

band and controlled by a selector switch on or near

the control box enclosure.

2.

This option eliminates the need to physically climb

up on the machine. This especially helpful with

machines of large work heights.

Optional hydraulic band tension is factory set.

DO NOT adjust the handwheel if supplied!

BAND LUBRICATOR

1.

For machines without the mist lubricated saw guides,

this option is for lubricating the saw band and sawing

area during the sawing process.

2.

See the instructions sent with the unit for information

on operation and adjustments.

DUST COLLECTOR

1.

See the literature sent with the unit for information

on installation, operation, maintenance and

adjustments.

HYDRAULIC TABLES (Continued....)

Summary of Contents for ZV-3620

Page 1: ...ZV 3620 Serial No 565 03101 to Band Sawing Machine Instruction Manual...

Page 6: ...2 MACHINE DIMENSIONS Continued INCHES 03 MILLIMETERS 1 mm FLOOR PLAN With HMD HYDRAULIC TABLE...

Page 9: ...5 MACHINE FEATURES FRONT VIEW...

Page 10: ...6 MACHINE FEATURES Continued FRONT VIEW With HMD HYDRAULIC TABLE...

Page 11: ...7 MACHINE FEATURES Continued REAR VIEW...

Page 12: ...8 MACHINE FEATURES Continued REAR VIEW With HMD HYDRAULIC TABLE...

Page 25: ...21 LUBRICATION DIAGRAM HMD TABLE OPTION REAR VIEW...