23

2.

To adjust system pressure:

(a)

Loosen the jam nut

counterclockwise

on the adjusting screw;

(b)

Start

the hydraulic motor by pushing the

Hydraulic Start

button;

(c)

Looking at the pressure gauge, turn the

adjusting screw

in

(clockwise)

to increase pressure,

out (counterclockwise)

to decrease it.

Pump Repair & Replacement

1.

DO NOT attempt to repair the hydraulic pump.

Return it to the factory for repair or replacement. Be

sure to specify the correct pump model and serial

numbers when returning the unit.

After the pump has been primed, run it

for several minutes while operating the

machine’s controls to purge entrapped air

from the pump and system. Check for oil

leaks while the system is being operated.

HYDRAULIC TABLE (Optional)

Bleeding Air From The System

1.

Run the machine for at least 30 minutes or until oil

is warm. Then:

(a)

Position the adjustable table

stops, located on the side of the table, to give full

table travel;

(b)

Place the

Table Feed Control

in

“FORWARD” to move the table cylinder rod to its

extended position;

(c)

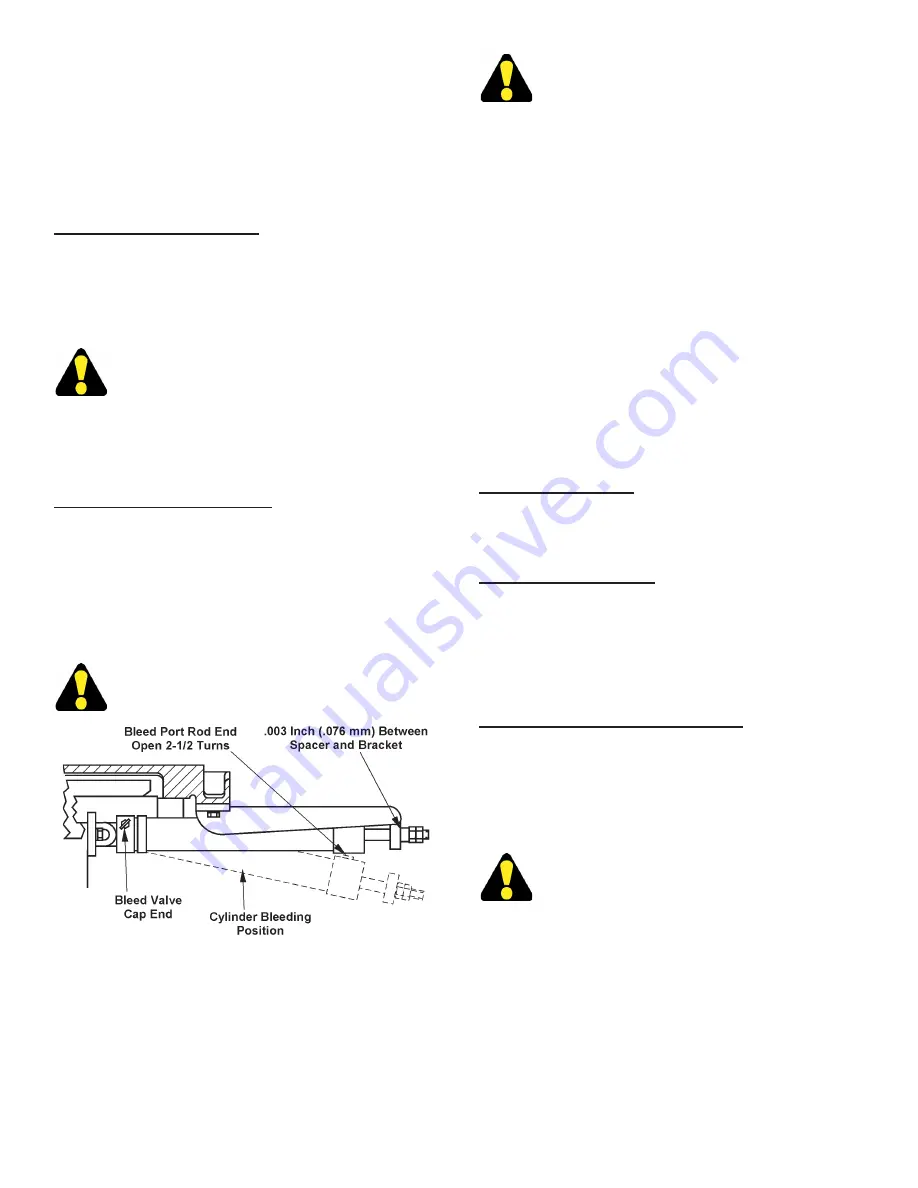

Remove the two (2) jam nuts

and spacer shown in the illustration.

Support the rod end of the table cylinder as

the rod is pulled out of the table bracket.

Bleeding Air From the Hydraulic System.

2.

Attach a length of plastic tubing to the bleed valve

on the rod end of the cylinder and route it into the

reservoir through the dip stick opening. Next:

(a)

Open the bleed valve on the cap end of the cylinder;

(b)

Move the

Table Feed Control

to “REVERSE”

and retract the cylinder.

Be certain to close the bleed port opposite the

end you are bleeding.

3.

Allow the cylinder to hang down to provide access

to the bleed port on the top of the rod end cap.

Then:

(a)

Close the bleed valve on the cap end

of the cylinder;

(b)

With a container under the

rod end of the cylinder, open the bleed port 2-1/2

turns

counterclockwise

;

(c)

Move the

Table Feed

Control

in “FORWARD” to fully extend the cylinder

rod;

(d)

Repeat steps 2 and 3 until all air is purged

from the system.

4.

Reinstall the table cylinder rod with spacer and jam

nuts, as shown in the illustration. Allow .003 inch

(.076 mm) clearance between the spacer and the

table bracket.

4.

See the

"Adjustment Summary"

for information on

all hydraulic adjustment procedures.

SAW GUIDES

Pivot Back-Up Inserts

1.

Reverse pivot back-up inserts for additional wear

life, then replace when all surfaces are worn.

Roller Back-Up Bearings

1.

These bearings are sealed and packed for life with

a special lubricant. They can be replaced by:

(a)

Removing the snap ring;

(b)

Pulling out the bearing

and shaft;

(c)

New bearings are easily installed with

a light press fit.

Automatic Mist Lubricated (Optional)

1.

Keep reservoir full and hoses clear. Follow the

manufacturer’s maintenance instructions for the

lubricator.

MACHINE CLEANING

Stop the machine when cleaning the machine

or opening bandwheel doors or covers.

1.

Keep the machine and its parts as clean as possible

to prevent excessive wear and damage.

3.

Metal chips and other waste materials may

collect around areas such as: saw guides,

table surface, T-slots, bandwheels, slides, etc.

Remove these materials as soon as possible.

The

DoALL Company recommends removing chip

collections at least twice per each eight (8) hour

shift, and more often with heavier use.

HYDRAULIC SYSTEM (Continued....)

Summary of Contents for ZV-3620

Page 1: ...ZV 3620 Serial No 565 03101 to Band Sawing Machine Instruction Manual...

Page 6: ...2 MACHINE DIMENSIONS Continued INCHES 03 MILLIMETERS 1 mm FLOOR PLAN With HMD HYDRAULIC TABLE...

Page 9: ...5 MACHINE FEATURES FRONT VIEW...

Page 10: ...6 MACHINE FEATURES Continued FRONT VIEW With HMD HYDRAULIC TABLE...

Page 11: ...7 MACHINE FEATURES Continued REAR VIEW...

Page 12: ...8 MACHINE FEATURES Continued REAR VIEW With HMD HYDRAULIC TABLE...

Page 25: ...21 LUBRICATION DIAGRAM HMD TABLE OPTION REAR VIEW...