SERV-US general checklist for preventive maintenance and repair-US en-2020-01

4/5

10

Extras for cantilever liftgates

Frequency

OK ?

Corrected

Rear closure platform, in travel position

Pressure against the rear frame, sealing, adjustment of the tilt cylinder extensions

Yearly

Platform behind rear doors, in travel position

Correct distancing from the rear doors, interference with the rear doors, adjustment of the tilt

cylinder extensions

Yearly

11

Practical tests

Frequency

OK ?

Corrected

General operation test with empty platform

•

Execute all movements minimum 3 times with all available control units.

•

Liftgate should operate smoothly and quietly through its full range of motion.

•

Check condition of articulation points (no excessive play).

•

Verify correct auto-tilt function at ground level (if applicable).

90 days 1750

cycles

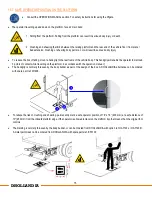

Dynamic weight test at 100% of the maximum rated lift capacity

•

Place the platform at rest on the ground.

•

Put a load equal to 100% of the maximum rated lift capacity at the center point of

maximum load.

•

Lift the platform. Check if lift capacity is sufficient. Check general operation and stability.

•

Check safe working speeds:

→

Lift & lower: max. 6” / sec

→

Hydraulic open and close: max. 10° / sec

→

Auto-tilt at ground level (if applicable): max. 4° / sec

Yearly

Overload test, adjustment of pressure relief valve

•

Place the platform at rest on the ground.

•

Put a load of 100% of the maximum rated lift capacity at the center point of maximum

load. Adjust the hydraulic pressure at the pressure relief valve so that the maximum

rated lift capacity is just reached.

•

Add max. 10% or max. 200 lbs overload (whichever is the least) at the center point of

maximum load. Adjust the hydraulic pressure so that the platform cannot lift the

maximum rated lift ca the overload.

•

Refer to procedure I-SERV-G-003 in the Maintenance and Repair Manual.

•

(Note: pressure should never exceed 220 bar / 3190 psi)

Yearly

DH-S slider liftgates: slide-in / out test

•

Slide liftgate in / out 3 times

•

Ensure sliding movement evolves smoothly, without juddering

•

Slide out and lift fully. Check correct alignment of the platform flush with the vehicle

bed.

180 days

3500 cycles

Hydraulic circuit general

No visible oil leaks during operation and at rest

90 days 1750

cycles

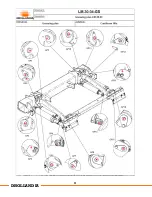

Summary of Contents for DH-L 3300 lbs

Page 17: ...16 DHOLLANDIA LMS 55 66...

Page 28: ...27 DHOLLANDIA...

Page 49: ...48 DHOLLANDIA...

Page 52: ...51 DHOLLANDIA 11 3 1 Installation of 3 Button Wander Lead OAE002 E0784 M S...

Page 53: ...52 DHOLLANDIA 11 3 2 Installation of cabin cutoff switch OAE510 15 E0393 S 15...

Page 59: ...58 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0580 EN CAP...

Page 60: ...59 DHOLLANDIA EF0585 US Serial Number EF0581 EN EF0563 EN EF0616 EF0562 EN...

Page 68: ...67 DHOLLANDIA...

Page 69: ...68 DHOLLANDIA...