SERV-US general checklist for preventive maintenance and repair-US en-2020-01

1/5

Checklist for preventative

maintenance and inspection

Work order #

Client PO #

Client :

Plate :

Mileage :

Address :

Model + S/N :

Contact phone :

City :

ST :

Zip :

Date :

GENERAL

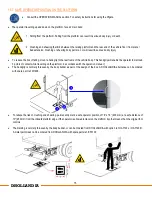

When “NOT OK”

, liftgate must be serviced or repaired prior to further use

1

Before getting started…

Frequency

OK ?

Corrected

Pressure wash

Clean liftgate thoroughly to make it ready for inspection

As needed

2

Documentation check, safety markings and decals

Frequency

OK ?

Corrected

Operation manual

Present in vehicle cab; complete

90 days 1750

cycles

Model ID decal, serial number decal, MAXIMUM RATED CAPACITY decal

Present, well legible and in good condition

90 days 1750

cycles

Marking of CENTER POINT OF MAXIMUM LOAD on platform

Present, well legible and in good condition

90 days 1750

cycles

Marking of SAFE OPERATOR POSITION on platform (if no foot controls)

Present, conspicuous, applied per installation

manual (min. 10” from inboard platform edge)

90 days 1750

cycles

Safety and operation decals

Present, complete, well legible and in good condition

90 days 1750

cycles

3

Controls and electrical wiring

Frequency

OK ?

Corrected

Main external control box, cover, installation to vehicle body

Condition, fastening to the vehicle body, undamaged

180 days

3500 cycles

Main battery disconnect switch in control box, dashboard switch in truck cabin

Condition, operation

180 days

3500 cycles

Switches and buttons, protective rubber covers

Condition, operation, automatic return to neutral position

180 days

3500 cycles

Wiring harnesses

Condition, secured with clamps and/or cable ties, undamaged

180 days

3500 cycles

Inside of main external control box, 15A fuse, spare fuse, electrical switches

Condition, dry, corrosion free, all wires secured

Yearly

2-hand operation at the main external control box (if applicable), safety switch

Operation, 2-hand operation not tampered with or altered in any way

180 days

3500 cycles

Safety switch (if applicable): switch-over between main external versus auxiliary controls

Operation, correct switching between main external controls and auxiliary controls

Yearly

Foot controls and their rubber buttons

Condition, operation, routing, securement and condition of the wiring harness

90 days 1750

cycles

Handheld remote control

Condition, operation, condition of holder or magnetic catch, spiral cable and plug(s)

90 days 1750

cycles

4

Electrical installation

Frequency

OK ?

Corrected

Batteries and battery connections

Yearly

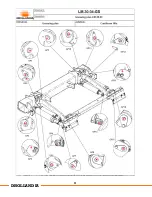

Summary of Contents for DH-L 3300 lbs

Page 17: ...16 DHOLLANDIA LMS 55 66...

Page 28: ...27 DHOLLANDIA...

Page 49: ...48 DHOLLANDIA...

Page 52: ...51 DHOLLANDIA 11 3 1 Installation of 3 Button Wander Lead OAE002 E0784 M S...

Page 53: ...52 DHOLLANDIA 11 3 2 Installation of cabin cutoff switch OAE510 15 E0393 S 15...

Page 59: ...58 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0580 EN CAP...

Page 60: ...59 DHOLLANDIA EF0585 US Serial Number EF0581 EN EF0563 EN EF0616 EF0562 EN...

Page 68: ...67 DHOLLANDIA...

Page 69: ...68 DHOLLANDIA...