55

DHOLLANDIA

14

QUALITY CONTROL AND PDI TEST

•

Finish the liftgate in accordance with local regulations.

•

Execute all functions min. 5 times to ensure the liftgate functions correctly. In particular:

1

Verify that the automatic tilt at ground level operates properly.

2

Verify that the end stops for the lift arms are strong enough and fit for purpose.

3

Verify that the platform in work position aligns level with vehicle floor.

4

Verify that the platform closes correctly in stow position.

•

Make sure that the platform will be clearly visible in public traffic:

1

Apply the RD/WH reflective marking tape on both sides of the platform.

2

Install the platform flags to the underside of the platform point.

3

If applicable, connect the flashing platform lights and verify their function.

•

If the operator is allowed to travel up and down on the platform by other means than original foot controls, mark a safe operator

position of

16” x 16” (

400 mm) at a safe distance of

10”

(250 mm) from the hazardous crushing area between the inboard platform

edge and the rear cross member of the vehicle floor.

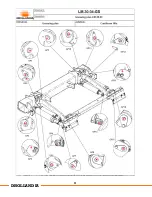

Summary of Contents for DH-L 3300 lbs

Page 17: ...16 DHOLLANDIA LMS 55 66...

Page 28: ...27 DHOLLANDIA...

Page 49: ...48 DHOLLANDIA...

Page 52: ...51 DHOLLANDIA 11 3 1 Installation of 3 Button Wander Lead OAE002 E0784 M S...

Page 53: ...52 DHOLLANDIA 11 3 2 Installation of cabin cutoff switch OAE510 15 E0393 S 15...

Page 59: ...58 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0580 EN CAP...

Page 60: ...59 DHOLLANDIA EF0585 US Serial Number EF0581 EN EF0563 EN EF0616 EF0562 EN...

Page 68: ...67 DHOLLANDIA...

Page 69: ...68 DHOLLANDIA...