11

DHOLLANDIA

5.3

GETTING STARTED

•

Many vehicle manufacturers issue important instructions on various aspects of the liftgate installation, specific to the brand and type

of chassis. Examples:

→

welding instructions or the prohibition to weld

→

instructions on chassis drilling and bolt-on connections to the chassis

→

recommendations on the use of hydraulic stabilizing legs

→

guidelines on fuses, electrical interfaces, and the connection of battery and ground, etc.

NOTICE

•

ALWAYS verify and ensure compatibility between the liftgate and the vehicle.

•

ALWAYS ensure compliance with the fitting and body building instructions issued by the vehicle manufacturer.

•

Make sure planned modifications to the vehicle chassis and body will not adversely affect the strength and integrity of the vehicle.

•

If the instructions of vehicle manufacturer conflict with the installation instructions issued by DHOLLANDIA (e.g. on fuse ratings,

etc.), contact your national DHOLLANDIA distributor for further advice. See contact info on page 4.

•

Verify if the installation kit is complete and that all parts needed to install the liftgate, are present.

•

Compare the voltage of the batteries with the voltage of the hydraulic power pack of the liftgate.

•

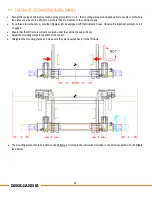

Compare the actual vehicle dimensions with the maximum installation parameters indicated in the INSTALLATION DRAWING or

technical documentation. If the actual dimensions go outside of the maximum installation parameters, DON’T continue and conta

ct

your national DHOLLANDIA distributor for further advice.

•

Verify and make sure that the vehicle chassis and body are strong enough to support the forces induced by the liftgate at its maximum

rated capacity. Refer to the instructions of the vehicle manufacturer for calculation and construction guidelines.

•

Execute the required stability and weight distribution calculations.

•

Make sure that the body is accurately fitted to the vehicle chassis.

•

Remove all objects that impede the installation of the liftgate (bumper bar, spare wheel carrier, pallet racks, tool boxes, etc.). If

necessary, consult with the vehicle manufacturer for replacement solutions (e.g. special spare wheel carriers, exhaust pipe

modifications, etc.).

•

Finish the liftgate in accordance with the road legislation of the country where the vehicle will be registered.

•

When connecting hydraulic couplings, make sure that the connections are clean. Don’t contaminate the hydraulic oil.

•

Grease all bearings and pins before putting the liftgate into service. Preferably, put grease in the bearings before mounting the

corresponding articulation pin.

•

After installation, work through the checklist of the Pre-Delivery Inspection (PDI) test. Make sure the final inspection is signed off by

an inspector who is not part of the installation team.

•

Do not pressurise any liftgate functions (LIFT / CLOSE) before the installation is fully finished.

•

During installation and testing, verify and make sure that the liftgate

and its moving parts don’t interfere with any of the vehicle

systems (e.g. the suspension, braking system, hydraulic and electrical circuits, etc.), or cause damage to them.

•

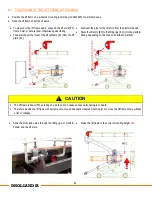

Do not release the locking bolts of the auto-tilt swing brackets before the liftgate installation is fully finished.

M

Summary of Contents for DH-L 3300 lbs

Page 17: ...16 DHOLLANDIA LMS 55 66...

Page 28: ...27 DHOLLANDIA...

Page 49: ...48 DHOLLANDIA...

Page 52: ...51 DHOLLANDIA 11 3 1 Installation of 3 Button Wander Lead OAE002 E0784 M S...

Page 53: ...52 DHOLLANDIA 11 3 2 Installation of cabin cutoff switch OAE510 15 E0393 S 15...

Page 59: ...58 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0580 EN CAP...

Page 60: ...59 DHOLLANDIA EF0585 US Serial Number EF0581 EN EF0563 EN EF0616 EF0562 EN...

Page 68: ...67 DHOLLANDIA...

Page 69: ...68 DHOLLANDIA...