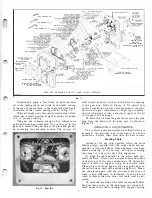

When a slight groove is cut in the planed surface

as shown in (t) FIgure 47, it is known as a pressure

bounce and indicates too great

a

pressure on the infeed

roll. To correct this, relieve the pressure on the infeed

roll by turning out pressure screw PLR-62, see Fig

ure 1 9.

When a piece of work is planed and the end cut

appears as in (3) Figure 47, it is known as a sniped

end. This indicates that the table is too loose and is

corrected by tightening the gibs on the table, refer to

Figure 15.

When the work shows feed roller marks as shown

in (4) Figure 47, the infeed roller pressure is too great.

Reduce the pressure on roller by turning out adjust

ment screws on top of right and left hand columns,

see Figure 1 9.

When the stock is put through the machine wrong,

that is against the grain, a chipped edge will result,

as shown in (5) Figure 47. Turn the wood around, (nd

for end, so that the cutter will cut with the grain and

you will get a nice, smooth, even cut.

When the material has a taper cut, that is from side

to side it indicates that the table is not parallel to the

cutter head, as shown in (6) Figure 47. In this case

all that is necessary is to adjust the table so that it is

parallel to the cutter head, refer to Figure 14.

Keep the table top clean and free of chips at all

times, so that no chips can get under the material

and cause gouges or scratches on under side of material.

ACCESSORIES

The sub-base, jointing attachment, and the grind

ing attachment are accessories which are available

and can be purchased as additional equipment.

No.

22- 1 02

Sub-Base Assembly

The sub-base assembly has been ruggedly designed

for mounting the Delta 1 3 x 5" thickness planer and

not only presents a machine of modern lines, but it can

also be kept in a neat condition. In addition, it pro

vides for mounting the machine at the correct work

ing height.

The overall dimensions of the sub-base are : 30"

wide, 16" deep, and 14" high. This unit is easily assem

bled as described under '"Assembly." Refer to Fig. 2.

No.

22- 1 06

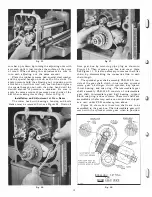

Grinding Attachment

When the knife blades in the cutter head are dulled

beyond the point where jointing them will not sharpen

them properly to produce a smooth cut, or if large

nicks should appear on the edges of the knife blades

that cannot be removed easily by jointing them, or

if a new cutting angle on the knife blade edge is de

sired, we suggest grinding the knife blades. This oper

ation is easily accomplished with a knife grinding

attachment which will grind a new cutting edge on

the knife blades.

This attachment is easily mounted to the top of

the planer. It has an adjustable stud at the front to

obtain the correct height and angle of its cup type

grinding wheel.

The positive indexing mechanism included with

this attachment is easily installed on the cutter head

pUlley. This mechanism permits each knife blade of

the cutter head to be ground on the same angle and

held firmly in position during the grinding operation.

No.

22- 1 07

Jointing Attachment

When the knife blades in the cutter head show

small nicks on the surface of their edges, or if the

cutting circle of the cutter head is not true, we sug

gest jointing the knife blades. This operation is easily

accomplished with a jointing attachment which brings

them to a true cutting circle while the cutter head is

rotating at normal operating speed (4200 rpm) .

This attachment is easily mounted to the table of

the planer without removing any parts. A self-locking

micro-adjustment for raising the jointing stone to the

knife blades in the cutter head is conveniently mounted

on this attachment for taking successive light cuts.

No.

22- 1 1 5

Shaving Hood

The shaving hood is another one of the accessories

to the Delta planer. It is attractively designed and

can be attached to the planer very quickly and easily.

Remove two hexagon nuts from the top of the

planer, one on the top of each column, the one in

the rear when facing the machine. You will notice the

shaving hood has two ears with holes in them. These

will fit the two studs from which the two hexagon nuts

have been removed. After placing the shaving hood

over these two studs replace the two hexagon nuts and

tighten securely.

The shaving hood when in place will fit over the chip

breaker. Once in place it will not be necessary to

remove it except when the knife blades in the cutter

head are to be resharpened with the Delta Knife grind

ing attachment. It is made of sheet steel and welded.

It has a standard 6 inch diameter opening at the top

where it wiIl connect to the regular dust collecting

system in the factory or location where it wiIl be used.

The shaving hood will keep the machine and the

work free and clear of chips at all times, thus enabling

the operator to see the work much better. The location

of the shaving hood will not cut off any light or inter

fere with the work at all. It will also reduce to a

great extent the possibility of the operator getting

any dust particles in his eyes.

Occasionally chips may become wedged between the

table roller and the table, these chips must be removed

or they might scratch or mar the work as it goes thru

the machine. These rollers should roll freely at all

times to insure proper feeding of the work, on the

planer.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......