ASSEMBLY

Remove the crate. Wipe the protective coating

thoroughly from the working parts of the machine.

Unpack the other items in the separate cartons which

come with the planer, and wipe the protective coating

from these parts.

Place the hand-wheel assembly on the machine by

slipping its hub over the hand-wheel shaft of the

raising mechanism which projects from the left side

of the base casting. Tighten the set screw in the hub

of the hand-wheel assembly against the flat of the

shaft by using the 3/16" hexagon wrench SP-3.

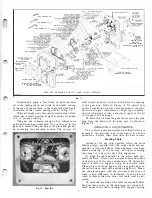

To assemble the sub-base proceed as follows: Set

two legs on end and fasten a tie angle to them by

using the %-16 x Va" hexagon head cap screws and

the %" split lockwashers. Attach the two tie angles

to the four legs as described above. Slip the motor

bracket assembly on the rear tie rod, then place a

set collar on each side. Fasten the tie rod to the tie

angle using the Yz-13 x

I"

hexagon head cap screws

and the Yz" split lockwashers. Place the two eye bolts

on the remaining front tie rod and thread a %-24

hexagon nut on each of them. Install the tie bar so its

two outer holes fall over the ends of the eye bolts let

ting it rest on the hexagon nuts. Place a %" split

lockwasher and a :Y;!"-24 hexagon nut on the end of

each eye bolt loosely.

Swing the motor bracket assembly down on the

front tie bar and match its holes with the two inner

holes of the tie bar. Insert a %-24 x 1" hexagon head

cap screw through each of the two holes in the tie

bar from the bottom, placing a %" split lockwasher

and a �/g"-24 hexagon nut on top, then secure the motor

bracket assembly in position by tightening these nuts.

In some cases the tie bar may be mounted on top of

the motor bracket assembly if necessary.

Fasten the side, front and rear panels to the cast

iron legs by means of the soecial 5

/

16-18 x Yz" truss

head machine screws provided with the sub-base as

sembly. Refer to Fig. 2.

The base of the machine has four tapped holes in

it which are used to mount it directly on the sub-base

assembly using the %-11 x 2" hexagon head cap

screw with a %" split lockwasher from beneath the

top of each leg and screwing the end of each cap screw

into the tapped hole of the base. The additional two

11/16" diameter holes in each tie angle of the sub-base

assembly are provided for mounting the machine to

a skid or permanently mounting it to the shop floor.

However, it is not necessary to bolt the machine down

as the base or sub-base is built to stand on any level

surface.

ST ARTERS AND ELECTRICAL CONNECTIONS

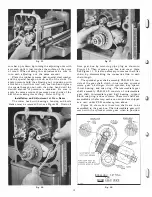

The magnetic starters available with start and stop

reset push buttons are conveniently mounted in the

left-hand column as shown in Fig. 4 so they become

an integral part of the machine. Mounting the starters

in this manner provides for a permanent safe connec

tion and permits the machine to be easily wired from

any convenient power outlet. All starters available for

this machine are open type (without box enclosure) ,

operate on AC current and are for either single or 3

phase motors only.

No. 49-386 Magnetic starter available for 220 volt

operation, open type (without box enclosure) with

heater coils.

No. 49-387 Magnetic starter available for 440 volt

operation, open type (without box enclosure) with

heater coils.

4

The following heater coils are available for the

above electrical starters :

PLR-151 Pair of heater coils for use with No. 49-386

magnetic starter. This pair of heater coils is used in

conjunction with a 3 hp, 3 phase, 230 volt motor and

have a rating of 7.2 amperes.

PLR-152 Pair of heater coils for use with No. 49-387

magnetic starter. This pair of coils is used in con

junction with a 3 hp, 3 phase, 440 volt motor and have

a rating of 3.5 amperes.

PLR-153 Pair of heater coils for use with No. 49-386

magnetic starter. This pair of coils is used in con

junction with a 3 hp, 1 phase, 230 volt motor and have

a rating of 17 amperes.

Please specify the motor horsepower, phase, volt

age, amperage and frequency when ordering the above

magnetic starters.

Use No. 49-389 three No. 12 gauge wire two feet

long armored cable when connecting the switch and the

motor. All three wires of the armored cable are used

when installing a three phase motor. Only two wires

of the armored cable are used when installing a single

phase motor and the remaining wire is easily removed.

Fig.

4.

Electrical Starter Mounted in Left-Hand Column Casting.

CONNECTING TO POWER LINE

When connecting the power line to the starter box

have a licensed electrician check the following :

1. The line voltage, phase and frequency match the

the motor name plate.

2. The overload heater coils used in the starter box

must be the right size for the full load amperage

rating of the motor.

3. The proper size of wire is used in connecting

the machine to the power line to obtain proper

voltage. Using too small a wire will cause an

excessive loss of power.

4. The fuse used has enough capacity to carry the

starting and full load current of the motor.

5. The magnetic starter is of the proper voltage so

its magnetic coil matches the line voltage.

6. Make sure the motor rotates in the proper di

rection.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......