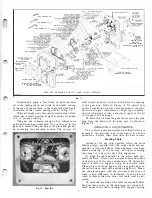

shifter assembly can be removed easily by loosening

the hexagon socket set screw in the outer indexing

collar using the 5/32" hexagon wrench SP-2, remov

ing the shifter handle from the shifter rod and slipping

the small indexing collar forward enough to remove

the steel pins and coil springs. Be sure when assem

bling this mechanism that the outer indexing collar

is tight against the large indexing collar before locking

it in position by tightening its hexagon socket set

screw. If this is not done properly slippage will occur

and the shifter assembly will not be held properly in

the feed position. Refer to Fig. 11.

When the shifter assembly is parallel to the column

casting the machine is in the idling position. Move

the shifter handle to the right to engage the machine

in the feed position.

Resetting Knife Blades In Cutter Head

The knife blades in the cutter head are set at the

factory to a true cutting circle of 2 9

/

16". If the knife

blades are removed or adjusted in any way, care must

be exercised in resetting them.

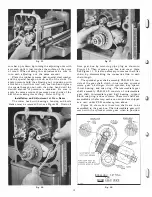

To reset the knife blades in the cutter head proceed

as follows: Turn the nine special hexagon head set

screws of the steel throat bar in the full amount using

the double end 5/16" open wrench J-40 provided

with the machine, and place this bar into the groove

of the cutter head. Screw one special collar adjusting

screw in the cutter head body giving it a few turns.

Slide a knife blade into the cutter head until its slotted

edge engages the collar of the adjusting screw. Engage

the slot on the opposite edge of the knife blade with

another special collar adjusting screw and

'

screw it

in the cutting head a few turns. Refer to Fig. 13.

Turn each of the nine special hexagon head adjust

ing screws in the throat bar out a few turns. Repeat

this operation as many times as necessary until the

throat bar is held lightly against the knife blade. Do

Fig.

36.

Checking Height of Knife Blade.

15

Fig.

37.

Adjusting Height of Knife Blade.

not turn each adjusting screw out the full amount

taking one at a time, because all nine screws must be

turned out gradually to insure the same amount of

pressure across the entire length of the knife blade.

To adjust the knife blade to the true cutting circle,

place the knife gauge provided with this machine over

the knife blade in the cutter head then turn the special

collar adjusting screws at each end of the kriife blade

until the knife blade just touches the center of the

knife gauge across its entire length. Tighten the knife

blade securely in place by turning each of the nine

special hexag�n head adjusting screws gradually out

in the throat bar as described above.

Each knife blade in the cutter head must be ad

justed as described above to maintain a true cutting

circle. Refer to Figs. 35, 36 and 37.

Important: An allowance of .008" for grinding

stock per blade has been provided in the knife gauge

which is furnished with this machine.

CARE AND SHARPENING OF

CUTTER HEAD KNIFE BLADES

The three high-speed steel knife blades in the cutter

head should plane the stock clean, and smooth without

exerting an unreasonable amount of force. After a

considerable amount of use, the knife blades in the

cutter head will become dull and will no longer cut

smoothly, but will tend to gouge the stock and leave

the surface rough. Continued operation of dull knife

blades will result in a great strain on the machine, the

cutter head assembly, and will cause decreased pro

duction.

If nicks should appear on the surface of the edge

of the knife blades, they should be eliminated, since

evidence will appear on the surface of the material

being planed. These nicks are easily removed by joint

ing or grinding or both depending upon the size of the

nick and condition of the knife blades.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......