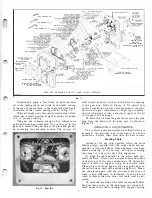

Fig.

21.

Removing Gear Box Cover.

Chip Breaker And Its Maintenance

!

he safety type c

?

ip breaker has a baffle type design

wh1ch forces the ch1ps to the rear of the machine in

stead of on the operating side of the machine. It pivots

on the front tie bar and automatically raises and lowers

with the serrated in-feed roll. The chip breaker has been

designed extra long purposely, as a safety measure,

to prevent the fingers of the onerator from coming in

contact with the revolving knife blades in the cutter

head, should he accidentally grasp this devise from the

operating side of the machine. Refer to Figure 40.

The rear curved surface of the chip breaker casting

which encircles the true cutting circle of the cutter

head should be checked from time to time to see if

any gum and pitch has collected on it. If an excessive

amount o

�

gum and pitch has collected on this portion

of the ch1p breaker casting, we suggest removing it

with Delta gum and pitch remover.

The chip breaker casting can be removed from the

Delta planer easily bv removing the four fillister head

cap sc�ews which hold it to the two support blocks

that plvot about the front tie rod. Refer to Fig. 13.

Also turn the cutter head to such nosition that the

knife blades in the cutter head will not be nicked or hit

?

y the chip breaker while removing it. After remov

mg the four fillester head cap screws, the chip breaker

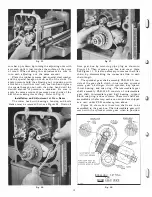

Fig.

22.

Adjusting Pressure Pad on Pressure Bar.

11

Fig.

23.

Assembling Connecting Link.

must be lifted up on one side and slid out and away

from the stop pin located in the column.

Adjusting Pressure Bar

The pressure bar is located directly behind the

cutter head and it rides on the newly planed surfaces

?f the stock only. Its function, as the name implies,

1S to hold th.e stock firmly on the table by applying

pressure on 1t. The pressure bar also insures a per

fectly smooth planed surface since it helps to prevent

chattering, waves in the material and any irregular

planing of the stock.

The pressure bar must be set within .002" of the

cutti�g cir�le of. the cutter head. If too much pres

sure 1� noticed 1tS pressure may be easily adjusted.

To adjust the pressure bar proceed as follows: Place

a square block of wood on the table surface at the rear

of the machine long enough to project past the cutter

head. Raise the table until the knife blades in the cut

ter head just barely scrape the surface of the square

block of wood, revolving the cutter head by turning

the cutter head pulley by hand through the opening in

the right-hand column.

Remove the special hexagon nut, special steel wash

er and the rubber pressure pad from the two studs

which project above the pressure bar. Adjust the pres-

Fig.

24.

Replacing Shear Pin.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......