(2) PLR-116 HEX NUT--{>

SPLIT LOCKWASHER SP-1705

(2) PLR-84

CAP (4) PLR-61

SP-231 SET

8REAKER STUD PLR-131

ADJUSTING SCREW (4) PLR-62

PLR-86-R CUTTER HEAD

(2)

(4) PLR-97

SP-777 CAP SCREW

i

(2)PLR-82 RUBBER PRESSURE

HAND SUPPORT RING PLR-112

,�-M(A)CH

�

CREW

(2) PLR-81 ADJUSTING

CHIP BREAKER PLR-6

6 PL -73

(4) SP-707 MACH

CBS-125

COVER PLATE

�

DRIVE SCREW (2) SP-2250

PLR-66

PLR-7 PESSURE BAR

''''.J

\

ACH SCREW (4) SP-707

_

:

CAP SCR

(2)

SP-3303

_.

_

PLR-III LEFT HAND SUPPORT

/

MACH

/

/

PLR-73

/

PLR-69 REAR TIE ROD

'\

I

�

,

'

�/'--

I

I

�

(2) SP-670 CAP

-

\

(2)

SP-1231 HEX

./

M

��?�l

DB

CfJ

E

�

F

./

I

(3) PLR-60

SPLIT

\

TH

�

OAT BAR

LOCKWASHER,

/

RIGHT HAND

.>'.

I

(271J

�

32

f

L

:

Ei

9SCR'"

(2) SP-1705

COLUMN

<.J

FRONT S

�!

ll

:�:

-

�����

O

PL

�

TE p

�

�

:

�

3 MATC

�

i

�:

�

�

!

5

�

F 3

STOP BUTTON (2) PLR-56

BLOCK ASSEMBLY (2) PLR -15-5

ADJ

/"'>

(6)

FIBER WASHER

LTA-462

SCREW (4) PLR-13

SP-2 HEX W RENCH

J-40 OPEN END W RENCH

CUTTER HEAD

BEARING PLR-136

_

PLR-68-S

_

�M��t�

(

�f�A

�

4

62

IN FEED

ROLL

PLR

48

RETAINING SCREW (4) PLR-13

HI-PRO-KE Y SP-2603

�

FIBER WASHER (4) HDP-122

SP-4 HEX W RENCH

PLR-150 KNIFE GAUGE

DUST SLINGER PLR-124

BEARING PLR-136

HOUSING PLR-16

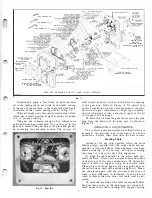

CUTTER HEAD, IN AND OUT- FEED ROLLS, CHIPBREAKER, PRESSURE

BAR AND RIGHT-HAND COLUMN ASSEMBLY

5-23-51

Fig.

13.

or lowering the adjusting nut by means of a small steel

rod

y,I"

in diameter and approximately 6" long. After

making the adjustment tighten the fillister head ma

chine screw in the adjusting nut support and take an

other trial cut as described above. Re-check the pieces

of wood by means of an accurate scale. If a slight cor

rection is needed, readjust the table until the setting is

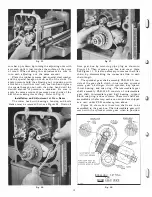

correct. Refer to Fig. 14.

Adjusting Table Gibs

The table casting has machined surfaces which

ride in relation to a machine surface of each column.

Between each side of the table casting and the columns

we have incorporated a steel gib to take up all play

between these machined surfaces. This adjustment has

been carefully made at the factory, but we suggest

checking the table to see if any play does exist.

If the table cannot be raised or iowered easily,

or if the table is too loosely set, an adjustment is

needed. To make this adjustment proceed as follows :

Loosen the hexagon jam nut which locks the cone

pointed adjusting screw and loosen or tighten each

adjusting screw approximately

Yz

turn. Lock each

screw after readjusting it by tightening its hexagon

jam nut. Be sure to loosen or tighten each screw the

same amount to obtain a good tight sliding fit between

the table and column castings. We suggest the op

erator adjust the uppermost screw first, then the bot

tom screw and finally the center screw. Refer to Fig. 15.

Adjusting Table Rollers and Thei r Maintenance

The table rollers (idlers) play an important part to

keep the stock feeding smoothly. These rollers prevent

the stock from dragging on the table surface while

the cutting head is planing the stock. The table rollers

have been accurately set at the factory .005" above

the table surface which is sufficient for most types

of wood.

Do not readjust these rollers unless it is absolutely

necessary. If the material drags to such an extent on

8

the table surface while it is being planed so that it

prevents the stock from being fed smoothly an ad

justment should be made. When making this adjust

ment proceed as follows: To accurately set these

rollers above the table surface it should be done by

means of a dial indicator. Run the dial indicator across

the entire surface of each roll to get them absolutely

parallel in relation to the table surface. If the dial

indicator shows that these rolls are not parallel a

correction should be made. Refer to Figs. 3 and 16.

Loosen the hexagon jam nut which locks each

hexagon head shoulder bolt located beneath each side

of the table casting and adjust each bolt the amount

Fig.

14.

Leveling Table.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......