60 cycle power use V-belts No. 49-175 68" long in

conjunction with the 7" motor pulley No. 1604.

To replace the V-belts, remove the hexagon nuts

and split lockwashers on the ends of the eye bolts

which project above the tie bar of the motor bracket

assembly. The V-belts can then be easily removed

from or installed on the cutter head pulley through

the opening in the right-hand column.

The correct belt tension is such that the V-belts

can be flexed approximately 1 inch out of line, using

finger pressure midway between the cutter head pulley

and the motor pulley.

To obtain the correct belt tension adjust the hexa

gon nuts on the eye bolts below the tie bar. The weight

of motor will give the V -belts the tension desired.

CUTTER HEAD PULLEY

PLUMB LINE

PULLEY

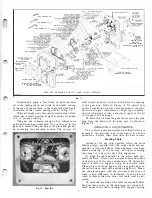

ALIGNING MOTOR PULLEY WITH CUTTER HEAD

PULLEY

Fig.

8.

After making all the adjustments necessary, place the

split lockwashers and hexagon nuts on the ends of the

eye bolts which project above the tie bar and tighten

them securely. Remount the belt guard cover plate

on the right-hand column and the end panel on the

sub-base assembly. Refer to Figs. 6 and 7.

LUBRICATION

The table rollers (idlers) and the thrust type ball

bearings of the elevating screws have been packed

with oil or grease before assembly at the factory and

need no further lubrication for their entire life.

The cutter head runs in two single row sealed and

shielded ball bearings which are prelubricated for their

entire life.

6

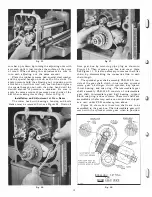

Fig.

9.

Raising Mechanism View from Beneath Base Casting.

The raising gears and elevating screws of the table

have been generously greased at the factory when

assembled. The gears and elevating screws of the

raising mechanism are readily accessible for additional

lubrication when required. Refer to Figs. 9 and 1 0.

The four guide blocks which carry the serrated in

feed and smooth out-feed rolls have porous bronze

bushings pressed into them. These bushings hold ap

proximately 30 per cent of their volume in oil, by the

oil seeping into the voids of the bushing material.

These bushings have been saturated with oil before

assembling the machine, consequently they will run

a considerable length of time without adding lubrica

tion. We suggest occasionally oiling these bushings

by removing the special hexagon lock nut and hexagon

socket adjusting screw, using the 5/16" hexagon wrench

SP-4, from each guide block assembly. The oil holes

are drilled through the guide block, but not through

the porous bronze bushings. Refer to Figs. 1 3 and 19.

Since these bushings are porous the oil is allowed

to seep slowly through the bushing material replacing

the oil which may have been lost from each porous

bronze bushing. By allowing the oil to seep through

the porous bronze bushings instead of having the

bushing drilled for oil, it is possible to prevent the

entrance of any dirt, dust, grit or any other type of

abrasive material from entering these bushings and

cause excessive wear. We suggest using a good grade

of SAE 40 oil which is suitable for these bushings.

Fig.

10.

Lubricating Gears of Raising Mechanism.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......