MOUNTING THE MOTOR

Before installing the motor, be sure it runs in the

right direction. The cutter head must be run clock

wise when viewed from the right side of the machine.

If the motor runs the wrong way, reverse it according

to the manufacturer's directions.

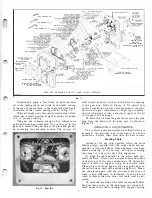

The motor mounting bracket shown in Figs. 2 and

5, has holes in it to receive NEMA No. 224 and No. 225

frame motors.

Remove the rear panel from the sub-base assembly.

Build a slanting platform to the motor bracket, as

shown in Fig. 5, so the motor can be placed on it

and slid onto the mounting bracket easily.

Slip the motor pulley on the motor shaft and slide

the motor on the motor bracket through the rear panel

opening, as shown in Fig. 6, and attach it to this

bracket by means of the hexagon head cap screws,

steel washers, split lockwashers and hexagon nuts

which are furnished with the machine.

Fig.

5.

Installing Motor.

To prevent excess wear and loss of power the V

belts must run true. For the V-belts to run true, the

pulley on the cutter head and the pulley on the motor

shaft must be in perfect alignment. First remove the

belt guard cover plate on the right hand column and the

end plate on the sub-base assembly and work through

these openings on the right side of the machine. To

line up the pulleys accurately, take an ordinary plumb

and place the cord in one of the V -belts grooves in the

pulley on the cutter head. Shift the motor pulley on

its shaft until the same groove of the motor shaft

pulley and the cutter head puliey have been lined up

with the plumb. Then tighten the set screw in the

motor pulley; Refer to Figures 2, 7, and S.

When lining up these pulleys be sure that the

planer is standing level.

If necessary the motor and its mounting bracket

can be shifted on the tie rods by loosening the set

collars which hold the mounting bracket in position

and shifting it in the desired direction. Be sure to

tighten each set collar on the tie rod against the motor

mounting bracket to hold it in position.

CHANGING V-BELTS AND THEIR

CORRECT TENSION

The V -belts for use with this planer are sold in

matched sets of three only. Do not replace one V -belt

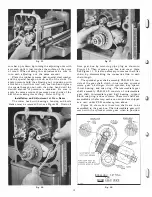

Fig.

6.

Adjusting Belt Tension.

at a time since this will cause all the V -belts to con

tinue to wear rapidly. This will also result in a great

strain on all the working parts of the machine as well

as excessive loss of power.

Use V-belts No. 49-176 71" long when operating

on 25 and 50 cycle power in conjunction with the

SYz" motor pulley No. 22-105. When operating on

Fig.

7.

V-Belt Drive.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......