D,_L1;A

Machine

-

M I

PM-1738

Revised:

1 0-17-51

22-8:

Thickness Planer Instruction Manual

"Patents Pending"

DELTA 13

X

5"

THICKNESS PLANER

Operating

and

Maintenance Instructions

The Delta 13 x 5" Thickness Planer is fully en

closed within its heavily ribbed fine grey iron castings

which provide minimum vibration and maximum ri

gidity between its working parts. This machine is

compact, ruggedly designed, has a large capacity and

is equipped for accurate work in cabinet, furniture,

sash, door and interior trim factories, contractors, box

manufacturers, pattern, job, woodworking and mainte

nance shops, schools and many other woodworking

and industrial plants and shops.

This machine will uniformly plane material up to

13" wide by 5" thick. It will take pieces as short as

6" long without requiring the use of a following block

and dress the stock as thin as 1/16" thick. The maxi

mum depth of cut is Ys" with a feed rate of 1 4 lineal

feet per minute. This means that 168" per minute will

be planed uniformly since the cutter head takes 75

cuts on each inch of material fed.

The overall dimensions of the machine are : 35"

wide, 26" deep and 39%" high.

The basic unit No. 22-101 consists of the following

standard parts: Base, right and left-hand columns,

table, safety type chip breaker, pressure bar and gear

box made of fine grey iron castings, safety type cutter

head complete with knife blades, ball bearings and

housings, matched set of 3 high-speed steel knife

blades, table rollers (idlers) , pOwer driven serrated in

feed and smooth out-feed rolls, gear box mechanism in

cluding a unique type clutch arrangement, 7" motor

pulley, matched set of 3 V-belts 68" long and wrenches.

The basic unit No. 22-1 20 is the same as No. 22-101

except that No. 22-1 20 is for 50 cycle current with No.

49-1 76 V-Belt and No. 22-1 05 8Yz" diameter pulley.

The motor, magnetic starters and electrical connec

tion from the starter to the motor are available and

can be purchased additional according to the cus

tomer's choice.

Accessories which may be purchased as additional

equipment are : 7" motor pulley No. 1 604, sub-base

including the motor mounting bracket No. 22- 1 02,

matched set of 3 high speed steel knife blades No.

22-104, 8Yz" motor pulley No. 22-1 05, knife grinding

attachment No. 22-1 06, jointing attachment No. 22-107,

one gallon can of lubricating oil for gear drive No.

22- 1 1 3,

3471,/'

diameter V-belt pulley No. 22- 1 1 4, 6"

shaving hood No. 22-115, box of medium grit (No. 60)

aluminum oxide mounted grinding wheels No. 22-116,

box of fine grit (No. 1 00) aluminum oxide mounted

grinding wheels No. 22-1 1 7, matched set of 3 V -belts

68" outside circumference for llse with 60 cycle 1 725

rpm motors No. 49-175, matched set of 3 V-belts 71"

outside circumference for use with 25 and 50 cycle

1425 rpm motors No. 49-176.

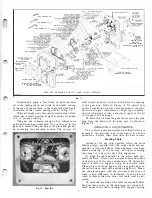

Fig. 1. Delta 13

x

5"

Thic:kness Planer.

Refer to the photographs, drawings, and Table 1

to identify the parts mentioned in the following

111-

structions.

CONSTRUCTION FEATURES

The base, right and left-hand columns, table, safety

type chip breaker, pressure bar and gear box are made

of fine grey iron castings to provide maximum rigidity

between the working parts and decrease vibrations to

a minimum to produce quiet smooth running operation.

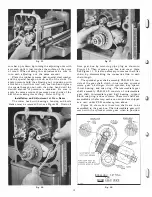

The cutter head runs in two single row sealed and

shielded ball bearings which are prelubricated for their

entire life. It has 3 high-speed steel knife blades which

can be easily adjusted and securely locked in the dove

tail grooves of the cutter head. The cylindrical cutter

head body is made from stress-proof steel and its high

speed steel knife blades are ground to close tolerances

to assure proper balance. Large chip clearance is pro

vided by the maximum knife angularity in the cutter

head to assure the least possible amount of cutting

friction.

Summary of Contents for Milwaukee PM-1738

Page 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Page 2: ......

Page 27: ......

Page 28: ......