14

Using the System

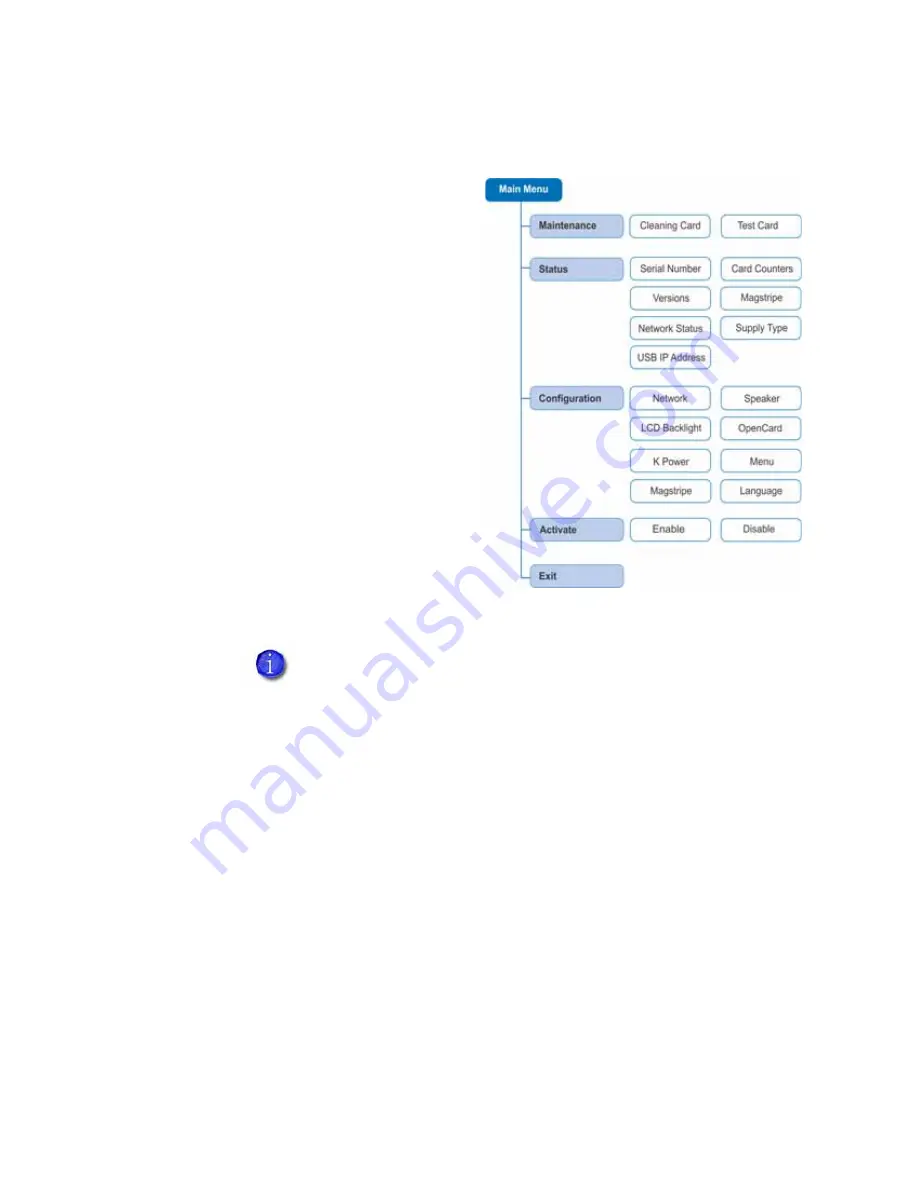

LCD Panel Menus

The

LCD

panel

shows

the

printer’s

menus

and

displays

printer

messages

or

conditions.

Refer

to

“Respond

to

Messages”

on

page

61

for

more

information.

The

menu

system

has

four

major

branches:

•

Use

the

Maintenance

menu

to

run

a

cleaning

card

or

a

test

card.

•

Use

the

Status

menu

to

see

settings

and

data

about

the

printer.

•

Use

the

Configuration

menu

to

change

settings.

•

Use

the

Activate

menu

to

enable

or

disable

the

printer

for

transport.

H

INTS

&

T

IPS

•

You

can

access

the

menu

system

when

Ready

displays

on

line

1

of

the

LCD

panel.

•

The

printer

returns

to

the

Ready

status

after

2

minutes

of

no

activity.

Changes

not

applied

are

lost.

•

To

leave

a

selection

without

changing

the

value,

press

the

up

or

down

arrow

key

until

Exit

displays,

and

then

press

the

E

NTER

key.

Use

the

Activate

menu

only

during

installation

or

removal

of

systems

that

require

activation.

Summary of Contents for SD Series

Page 1: ...Datacard SD Series Card Printers User s Guide March 2014 Part No 527400 001 Rev A ...

Page 8: ...viii ...

Page 14: ...2 Introduction ...

Page 22: ...10 About the Printer ...

Page 34: ...22 Using the System ...

Page 38: ...26 Printing Cards ...

Page 46: ...34 System Maintenance ...

Page 106: ...A 16 SD460 Laminating System ...